- Single Arm Load Controller with Dual Stage or Digital Valve Control

- Volume correction available to ASTM D1250-04

- Volume correction can be by combination of temperature, pressure and density inputs

- Applications tailored for Volumetric or Mass frequency flowmeters

- Multi compartment loading/unloading with operator prompts

- Stand-alone printer docket with compartment and summary details

- Allows quadrature flow input to ISO 6551 level B pulse security

- Allows for non-linear correction of flowmeters “K-Factor”

- Loads can be based on Gross Volume, Net Volume or Mass totals

- Can operate in Preset or On-Off batch mode (plus special mode for tuning)

- Provision for Deadman Timer with Alarm and Emergency Stop outputs

- Special start sequence provides Safety and Authorisation

- No-flow, leakage and overflow error detection

- External Emergency Stop logic input

- Allows for permissive for protective Earthing and Overfill with prompts

- Provision for gantry isolation or pump demand output

- ID Access validation available by ID-Pin number or ID-Tag (safe area only)

- Storage of 10000 logs records (500 latest transactions) with time and date stamp

- “User Tags” can be selected for custom text (or second language) on display

- Site and Delivery specific information can be entered during Start Sequence

- Custom codes (Product & Transport) can be setup via supporting 500-LP software

- Selectable protocols on serial ports including Modbus RTU and Printer output

- Backlit display & LCD backup on power fail to satisfy Custody Transfer requirements

- IECEx/ATEX and CSA approved Exd enclosure

- 500-Series DataMod software available for collection and reporting of delivery data

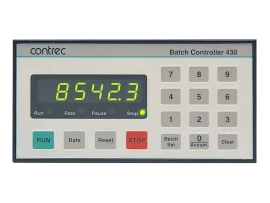

Contrec 515 Load Computer (LP01)

The Contrec Load Pro-B Load Controller is designed for various applications in single-arm loading systems. This user-friendly 5-key controller features Dual Stage or Digital Valve Control, ensuring the precise and reliable delivery of preset amounts of liquid products. It accepts frequency flow input from volumetric or mass flowmeters and can also process a quadrature signal for ISO 6551 level B pulse security. Additionally, it can incorporate temperature, pressure, and density inputs for accurate volume correction. The controller can be set to load based on either volume or mass preset quantities.

The Batch Controller prompts users for a valid User Access ID (ID-Tag or Pin-Number) and gathers task-specific information before starting the delivery process. This Access ID and the relevant data are stored as part of the transaction record, which can be accessed by external databases. The controller includes a pump demand output and emergency stop inputs to ensure safe and controlled delivery of products in single-arm loading applications.

A series of start sequences guarantees that loading or off-loading is performed safely and accurately. It allows for custom transaction information, compartment numbers, preset values, and permissive inputs to be manually entered or confirmed before the loading or off-loading begins.

Data Sheet: 515-Load Pro-B Load Computer – Datasheet