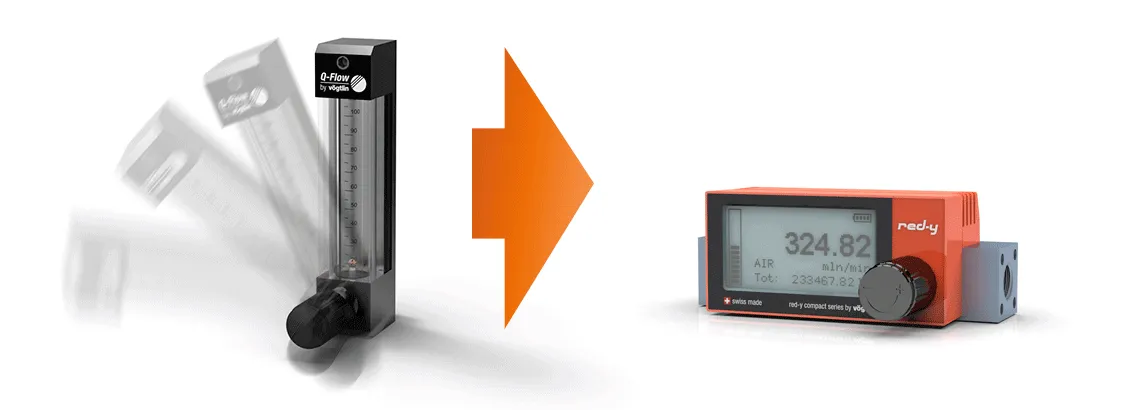

Comparison between Variable Area Flow Meter and Mass Flow Meter often compare of Volumetric Flow and Mass Flow Measurements.

Advantages of Mass Flow Over Volumetric Flow Measurements

- Mass Flow meter is having widest Turndown Ratio, Fast Response Time, High Accuracy and also High Repeatability

- Mass Flow Rate independence to pressure and temperature changes

- Pressure and Temperature Compensation does not require direct Mass Flow Measurements hence improve the cost-effectiveness of gas flow measurement

VA-Flow Meter v.s. Mass Flow Meter

Industrial flow measurement applications often require higher accuracy and pressure and temperature compensation, which is impossible to achieve with conventional Variable Area Flow Meters.

Hence Variable Area Flow Meters are susceptible to pressure and temperature changes. 1 Bar pressure changes in the process can generate an error of 50% in gas flow measurements. Therefore the flow compensation of Mass Flow Meters creates repeatability.

Common Variable Area Flow Meter in flow measurement possible only with Vertical Installation; however, smart Digital Mass Flow Meters provide installations flexibility both horizontally and vertically. In the past, the Variable Area Flow Meters having great advantages of no power supply required, however with innovation, now Mass Flow Meter with AA Battery Powered available without compromise of measurement accuracy.

The latest MFC’s and the Red-y compact from Vögtlin Instruments could also be called “digital VA-meters.” The readout is visual. These instruments are powered by an external power source or by a built-in battery. Hence optional control valve is manually operated.

MFC’s offer a solution with much lower measurement uncertainties and clear measurement units compared to mechanical flow meters. As a result of variations in the process pressure, the ‘digital VA-meter’ may well show a different measured value – because the control valve is manually operated – but it is, nevertheless, correct and unambiguous in terms of units of measurement. After all, they are mass flow meters! This is not possible with a mechanical VA-flow meter, the scale that is only valid for certain pressure and temperature.

There are several other advantages to mention: accuracy, linearity, greater turndown (ratio of full scale to minimum usable readings), mounted vertically or horizontally, vertical with the flow down, multiple gas curves in the electronic memory, etc. All of these make the switch from a VA-flow meter to a thermal flowmeter very logical.

The ultimate?

These are MFC’s that are given a set point and then independently control the flow to the set value. For example, Sierra Instruments’ 100-series or Vögtlin Instruments’ smart series. Both product lines can be equipped with a control valve. The setpoint is offered via the integrated display or analog and serial signals. In addition, various communication protocols, e.g., Modbus, Profibus, Industrial Ethernet, are available for recording and further automation.

The valve is opened so far that the measured value corresponds to the setpoint value. For example, the MFC will automatically open the valve a little further if the supply pressure drops. If the upstream pressure rises again, the control valve will close a bit. MFC’s are intelligent instruments for accurate flow measurement and control and offer much-added value over VA-flow meters.

Why an MFC?

Reasons for gas flow applications in laboratories or test facilities to choose MFC’s or mass flow controllers over Variable Area (VA) meters are:

– Significantly higher accuracies

– Less measurement uncertainty

– Much greater turndown

– Units of measure are clear

– Pressure and temperature effects are negligible.

– Measurement signals can be used for registration and automation

– Suitable for validation of processes

VA-flow meters are simple and price-wise, quite interesting. However, the user must be aware of the uncertainties that can ultimately lead to measurement errors in the order of tens of percent. MFC’s outclass VA meters in every aspect.