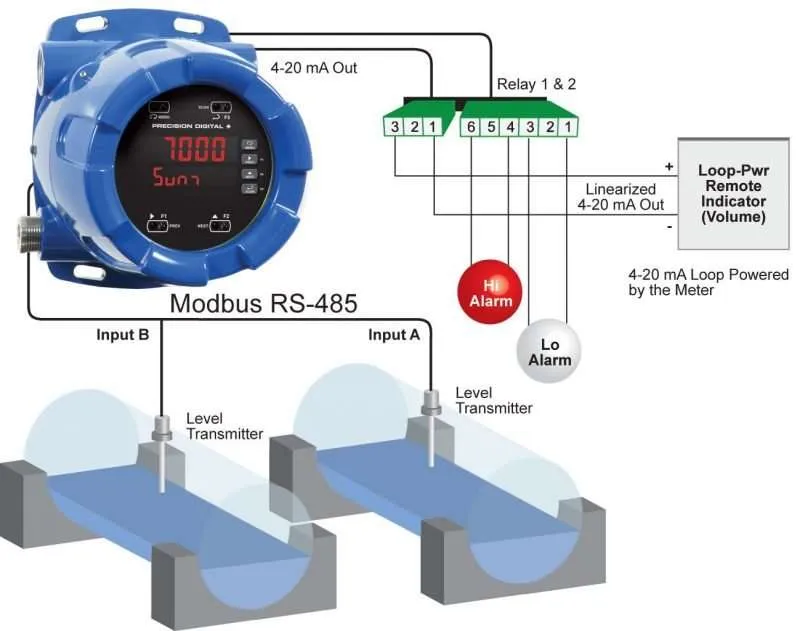

The ProtEX-MAX™ PD8-6081 feet & inches Modbus® scanner offers all the functionality of the ProVu PD6081 as a fully FM, CSA, ATEX, and IECEx approved explosion-proof product. It displays level information on a specially designed feet & inches display, instead of the usual decimal format. It is the ideal display for hazardous areas with Modbus level or multivariable transmitters and is capable of scanning up to 16 Modbus process variables. Its unique feet & inches upper LED display can indicate up to 99 feet, 11 and 15/16 inches. The 6-digit lower display can indicate units, tags, or other variables such as volume, temperature, or density. The PD8-6081 also has dual analog inputs, for integrating traditional 4-20 mA or voltage inputs in the display scanning. The scanner can be setup as a Modbus master, slave, or snooper. Various math functions may be applied to the analog or Modbus inputs, such as addition, difference, average, and ratio. The PD8-6081 includes a 24 VDC power supply to drive the transmitter and can be equipped with up to four internal relays and two 4-20 mA outputs. It can be programmed and operated without opening the housing by using the built-in SafeTouch® through-glass buttons.

Precision Digital PD8-6081 ProtEX-MAX Modbus Scanner

Quick Overview

- Input: Modbus with five-wire RS-485 for up to 16 Modbus process variables; two analog inputs, each separately field selectabe;

0-20 mA, 4-20 mA; ±10 VDC (0-5, 1-5, 0-10 V); Modbus PV (slave) - Display: Dual-line 6-digit, 0.60″ (15 mm) & 0.46″ (12 mm). Upper feet and inches display: Up to 99 ft, 11 and 15/16 inches.

- Enclosure: Smooth die-cast aluminum explosion-proof; NEMA 4X, 7, 9/IP68

- Power: 85-265 VAC or 12-24 VDC option

- Operating Temperature: -40 to 65°C

Features

- SunBright Display Standard

- Display level in feet and inches

- Modbus RTU master, slave, or snooper mode with RS-485 serial communications

- Master mode to can up to 16 Modbus PVs from Modbus level or multivariable transmitters

- Snooper mode to scan up to 16 Modbus PVs polled by a different Modbus master

- Up to four math channels for addition, difference, average, ratio & more

- SafeTouch® through-glass button programming

- Isolated 24 VDC @ 25 mA transmitter power supply

- 0-20 mA, 4-20 mA, 0-5 V, 1-5 V, and ±10 V inputs

- Onboard USB and ScanView programming software

General

Input/Output: Modbus RTU over RS-485, Two analog inputs (4-20 mA, ±10 V)

Display: Upper feet & inches display: 0.60″ (15 mm) high with feet & inches designations. Lower display: 0.46″ (12 mm) high. Both are 6 digits (-99999 to 999999), red LEDs.

Feet & Inches Display Range:0″ 00″ 0/16″ to 99″ 11″ 15/16″

Display Intensity: Eight user selectable intensity levels

Display Scan Rate: Master/Snooper: 1/second to once every 99.9 seconds. Slave: Dependent on master device (e.g. PLC)

Overrange: Display flashes 999999

Underrange: Display flashes -99999

Display Assignment: The top display may be assigned to PV (process values), Ch C (math channel), PV & units, tag & PV, tag-PV-units, C & units, tag-C-unit, Set point 1-8, max/min PV, max/min C. The bottom display may be assigned to all of the above, tag, or off. The tag and units are displayed alternately for 2 sec, when selected. Different tags & PVs may be selected to display on the top and bottom displays at the same time.

Programming Methods: Four through-glass SafeTouch buttons, four mechanical buttons behind glass, digital inputs, PC and ScanView software, or Modbus registers.

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels:Logic High: 3 to 5 VDC; Logic Low: 0 to 1.25 VDC

Noise filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of calibrated span

Recalibration: All ranges are calibrated at the factory. Recalibration is recommended at least every 12 months.

Max/Min Display: Max (Peak) / min (Valley) readings reached by the process are stored until reset by the user or until power to the meter is cycled.

Password: Three programmable passwords restrict modification of programmed settings.

Non-Volatile Memory: All programmed settings are stored in nonvolatile memory for a minimum of ten years if power is lost.

Power Options: 85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max, or optional sku with 12-24 VDC ±10%, 15 W max.

Fuse: Required external fuse: UL Recognized, 5 A max, slow blow; up to 6 meters may share one 5 A fuse.

Isolated Transmitter Power Supply: Terminals P+ & P-: 24 VDC ± 10%. Isolated from the input at >500 V. Jumper selectable for 24, 10, or 5 VDC supply (internal jumper J4). All skus transmitter supply rated @ 25mA max.

Normal Mode Rejection: Greater than 60 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output or output-to-P+ supply.

Overvoltage Category: Installation Overvoltage Category II: Local level with smaller transient overvoltages than Installation Overvoltage Category III.

Environmental:

T6 Class operating temperature range Ta = -40 to 60°C

T5 Class operating temperature range Ta = -40 to 65°C

Max Power Dissipation: Maximum power dissipation limited to 15.1 W.

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Enclosure: Explosion-proof die cast aluminum with glass window, corrosion resistant epoxy coating, color: blue. NEMA 4X, 7, & 9, IP68. Default conduit connections: Four ¾” NPT threaded conduit openings and two ¾” NPT metal conduit plugs with 12 mm hex key fitting installed. Additional conduit opening configurations may be available; verify quantity and sizes on specific device labeling during installation.

Mounting: Four slotted flanges for wall mounting or NPS 1½” to 2½” or DN 40 to 65 mm pipe mounting.

Dimensions: 6.42″ x 7.97″ x 8.47″ (W x H x D) (163 mm x 202 mm x 215 mm)

Weight: 16.0 lbs (7.26 kg)

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant

Connector Type: Micro-B receptacle

Cable: USB A Male to Micro-B Cable

Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit,

Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit

Power: USB Port

Modbus Serial Communications

Meter Address/Scanner ID: 1 – 247, 256-259 (for Volts and mA).

Baud Rate: 300 – 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 – 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Operating Modes:

MASTER: Processes data read from Modbus RTU slave devices. It polls up to 16 process variables from 1 to 16 slave devices. The Master is capable of scanning the selected PVs, scale the data, trigger relays, perform math operations, and drive the analog outputs.

SNOOPER: Listens to the Modbus traffic and picks up a specific register or registers being polled by a master device from a specific slave device and processes the data being read. The Snooper mode handles the data the same way as the Master.

SLAVE: Processes data sent to it from a Modbus RTU master device.

PV Number: PV1–PV16 Enable or disable the process variables to be polled by the Master.

Slave ID: Assign the slave ID or address (1-247, 256-259 for mA or volts inputs) containing the process variables to be displayed by the selected PV.

Function Code: Select which Modbus function code (03, 04, or 65) to use in reading the slave device.

Register Number: 5 digit: 30001-39999, 40001-49999, or 1-65,536

6 digit: 300001-365536 or 400001-465536 (Function Code 65 N/A here) Specifies which register(s) to read in the slave device. Range is dependent on Function Code selection (65, 04, or 03) and digits selection (5 or 6).

Data Type: Select the data format that the slave device uses. Select between Short integer (2 byte), Long integer (4 byte), or floating point (4 byte), Signed or Unsigned (integer only) and byte order: 1234, 4321, 2143, or 3412 (big-endian vs. little-endian, or swapped).

Poll Time: 1.0 to 99.9 sec. Time between read-commands (Master mode).

Slave Response Timeout: 0.0 to 99.9 seconds: Time allowed for the slave to respond before the scanner generates a communication break condition. The master polls the slave 3 times before starting the response timeout timer. Slave/Snooper mode: Time the scanner will wait for new data before going into break condition. Slave mode: Programming 0 disables the timeout; the last value received will be displayed indefinitely.

Communication Breakdown: Displays “brEAK” after the Master has polled the slave device 3 times and the response timeout has elapsed. The Snooper and Slave modes go into break condition after no new data is received within the response timeout window. Relays can be programmed to go on, off, or ignore the break condition. The analog outputs can be setup to generate a fixed mA current when a break condition is detected.

Programmable Constants: Constant P (Adder): -99999 to 999999, default: 0.000; Constant F (Factor): 0.00001 to 999999, default: 1.000

Math Functions: Addition, difference, absolute difference, average, multiplication, division, max of A or B, min of A or B, draw, weighted average, ratio, concentration. See instruction manual for details.

Tag & Units: 6-character, independent tag and units for each PV and math channel.

PV Format: PD6080 default: Decimal format. PD6081 default: FT & IN, 1/8th or 1/16th; decimal format may be selected for bottom display indication. Display Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd

Float Decimal Point: Select the number of decimals to use for the floating point data expected from the slave or master device (this is independent from the display decimal point selection).

PV & Math Scaling: All PVs and math channels may be scaled to represent the input data in any engineering unit.

Example: Level transmitter = 999.999 inches; to display in Ft-In-1/16th scale input 2 to display 83 Ft – 4 In – 0/16th.

Scan Mode: Automatic: 1.0 to 99.9 seconds.

Manual: Front panel or digital inputs

Go on alarm: Continues scanning after an alarm is detected

Stop on alarm: Goes to the alarmed PV and stops scanning; press Scan to resume scanning.

Relays

Rating: 2 or 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 W) @ 125/250 VAC for inductive loads.

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Electrical Noise Suppression: A suppressor (snubber) should be connected to each relay contact switching inductive loads to prevent disruption to the microprocessor’s operation. Recommended suppressor value: 0.01 µF/470 Ω, 250 VAC (PDX6901).

Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

Relay Operation: automatic (non-latching), latching (requires manual acknowledge), sampling (based on time), pump alternation control (2 to 8 relays), Off (disable unused relays and enable interlock feature, manual on/off control mode).

Relay Reset: User selectable via front panel buttons, digital inputs, or PC.

1. Automatic reset only (non-latching), when input passes the reset point.

2. Automatic + manual reset at any time (non-latching).

3. Manual reset only, at any time (latching).

4. Manual reset only after alarm condition has cleared (latching).

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay.

Auto Initialization: When power is applied to the scanner, relays will reflect the state of the input to the scanner.

Isolated 4-20 mA Transmitter Output

Output Source: Process Variable 1-16, math channels C1-C4, set points 1-8, or manual control mode

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated: 4.000 to 20.000 = 4-20 mA output

Analog Output Programming: 23.000 mA maximum for all parameters: Overrange, underrange, max, min, and break

Communications Break: Programmable mA output when a slave device does not reply within the response timeout

Accuracy: ±0.1% of span ± 0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µA/°C max from -40 to 0°C ambient

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All skus @ 25 mA max.

External Loop Power Supply: 35 VDC maximum

Output Loop Resistance:

| Power supply | Minimum | Maximum |

| 24 VDC | 10Ω | 700Ω |

| 35 VDC (external) | 100Ω | 1200Ω |

Dual Process Input

Two Inputs: Two analog inputs, each separately field selectable: 0-20 mA, 4-20 mA; ±10 V (0-5, 1-5, 0-10 V)

PV Analog Channel ID: Ch-A mA: Assign PV to ID 256 or Ch-A volt: 257; Ch-B mA: Assign PV to ID 258 or Ch-B volt: 259

Accuracy: ±0.03% of calibrated span ±1 count, square root & programmable exponent accuracy range: 10-100% of calibrated span

Temperature Drift: 0.005% of calibrated span/±C max from 0 to 65°C ambient, 0.01% of calibrated span/°C max from -40 to 0°C ambient

Signal Input Conditioning: Linear, square root, programmable exponent, or round horizontal tank volume calculation

Multi-Point Linearization: 2 to 32 points for PV1 and PV2

Programmable Exponent: 1.0001 to 2.9999

Low-Flow Cutoff: 0-999999 (0 disables cutoff function) for PV1 and PV2

Input Impedence: Voltage ranges: greater than 500 kΩ

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

Current ranges: 50 – 100Ω (depending on resettable fuse impedance)

Input Overload: Current input protected by resettable fuse, 30 VDC max. Fuse resets automatically after fault is removed.

Calibration Range:

| Input Range | Minimum Span Input 1 & Input 2 |

| 10Ω | 700Ω |

| 100Ω | 1200Ω |

Digital Inputs and Outputs

Channels: 4 digital inputs & 4 digital outputs per module

System: One expansion module may be added for a total of 8 inputs & 8 outputs

Note: The jumper located between the RJ45 connectors must be removed on the expansion module.

Digital Input Logic: High: 3 to 5 VDC; Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC; Low: 0 to 0.4 VD

Source Current: 10 mA maximum output current

Sink Current: 1.5 mA minimum input current

+5 V Terminal: To be used as pull-up for digital inputs only. Connect normally open pushbuttons across +5 V & DI 1-4. Warning: DO NOT use +5 V terminal (pin 1) to power external devices.

Function Assignment: The on-board digital inputs (1-4) are designed to mimic the behavior of the front panel buttons (Menu, F1, F2, & F3). If you wish to change their behavior, re-assign F1-F3 to the desired function, then change the corresponding digital input to match.

4-Relay Expansion Module

Relays: Four Form A (SPST) rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (approx. 50 watts) @ 125/250 VAC for inductive loads.

Dual Analog Output Expansion Module

Outputs: Two passive 4-20 mA analog outputs

Scaling Range: 3.000 to 23.000 mA for any display range

Product Ratings and Approvals

FM Enclosure:Type 4X; IP66

Class I, Division 1, Groups B, C, D

Class II, Division 1, Groups E, F, G

Class III, Division 1, T5/T6

Class I, Zone 1, AEx d, IIC Gb T5/T6

Zone 21, AEx tb IIIC T90°C; Ta -40°C to +65°C

T6 Ta = -40°C to +60°C; T5 Ta = -40°C to +65°C

Certificate Number: 3047283

CSA: Class I, Division 1, Groups B, C, D

Class II, Division 1, Groups E, F, G

Class III, Division 1

Class I Zone 1 Ex d IIC

Zone 21 Ex tb IIIC T90°C

-40°C < Tamb. < +60° C; Temperature Code T6

-40°C < Tamb. < +65° C; Temperature Code T5

Enclosure Type 4X & IP66

Certificate Number: 2531731

ATEX: II 2 G D Ex d IIC T* Gb

Ex tb IIIC T90°C Db IP68

Ta = -40°C to +*°C

*T6 = -40°C to +60°C

*T5 = -40°C to +65°C

Certificate number: Sira 12ATEX1182

IECEx: Ex d IIC T* Gb

Ex tb IIIC T90°C Db IP68

Ta = -40°C to +*°C

*T6 = -40°C to +60°C

*T5 = -40°C to +65°C

Certificate Number: IECEx SIR 12.0073

ScanView Software

ScanView software allows for the programming and monitoring of ProVu, ProtEX-MAX, and Helios series Modbus scanners. Use ScanView to program, monitor, and datalog using a PC. The PVs and math channels may be selected to display on the monitoring screen independently, and the monitoring screen can be customized so each has a configurable unit and tag. Even the display number colors may be changed. All 16 PVs, math channels, and their units and tags may be logged. The data is logged on the PC, and is available for use in common tools like Microsoft Excel. All configuration data can be saved to a file for future use.

Click here for more information about ScanView

Applications

Signal Input Conditioning

Non-linear input signals (i.e. weirs & flumes, differential pressure, etc.) can be linearized with the ProtEX-MAX’s simple to use built-in signal input conditioning, such as: square-root extractor, exponential linearizer, round horizontal tank linearizer, or the ProtEX-MAX powerful general purpose 32-point linearizer (32 point for PV1 & PV2 only – all other PVs use two linearization points).

Weir Flow Calculated Using Exponential Signal Input Conditioning

Round Horizontal Tank Signal Input Conditioning

Data Sheet: LDS8-6080_A{web} Datasheets

Instruction Manual:LIM8-6080_0 Instruction Manuals

Quick Start Manual: