The PD7000 is a member of the ProVu series of 1/8 DIN digital panel meters that accepts a direct temperature input from a wide range of temperature measurement devices (type J, K, T, E, R, S, B, N, and C thermocouples and 100 or 1000 Ω platinum, 10 Ω copper, 120 Ω nickel RTDs). It displays the measured temperature in either degrees Fahrenheit or degrees Celsius on a dual-line, 6-digit display that is available with optional Sunbright® sunlight readable LEDs. The PD7000 temperature indicator includes automatic cold junction compensation for thermocouples and the ability to average up to ten (10) RTD sensors. Like all ProVu meters, the PD7000 temperature meter includes UL / C-UL listing and CE marking, a NEMA 4X front, and AC or DC power options. ProVu meters can be equipped with up to four internal relays, a 4-20 mA output and Modbus® RTU serial communications. The PD7000 can be programmed via the front panel pushbuttons or free MeterView® Pro software.

Precision Digital PD7000 ProVu Temperature Digital Panel Meter

- J, K, T, E, R, S, B, N, C Thermocouples

- 100 or 1000 Ω Platinum, 10 Copper, 120Ω Nickel RTDs

- 1° or 0.1° Resolution

- Averages up to 10 RTD Sensors

- Automatic Cold Junction Compensation

- NEMA 4X, IP65 Front

- Universal 85-265 VAC or 12/24 VDC Input Power

- Large Dual-Line 6-Character Display, .60″ & 0.46″

- Programmable Displays & Function Keys

- Optional SunBright Display skus for Outdoor Applications

- 2 or 4 Relays + Isolated 4-20 mA Output Options

- External 4-Relay & Digital I/O Expansion Modules

- USB, RS-232, & RS-485 Serial Communication Options

- Modbus® RTU Communication Protocol Standard

- On-Board Digital Input

- Onboard USB and MeterView® Pro Programming Software

Display: Upper display: 0.60″ (15 mm) high. Lower display: 0.46″ (12 mm) high. Both are 6 digits (-99999 to 999999), red LEDs.

Resolution: 1° (up to four digits) or 0.1° (up to five digits)

Display Intensity: Eight intensity levels

Display Update Rate: 5/second (200 ms)

Front Panel: NEMA 4X, IP65

Programming Methods:Four front panel buttons, digital inputs, PC and MeterView Pro software, Modbus registers.

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels: Logic High: 3 to 5 VDC Logic Low: 0 to 1.25 VDC

Noise filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of span

Recalibration: Recommended at least every 12 months.

Max/Min Display: Max / min temperature readings are stored until reset by the user or until power to the meter is cycled.

Non-Volatile Memory: All programmed settings are stored in nonvolatile memory for a minimum of ten years if power is lost.

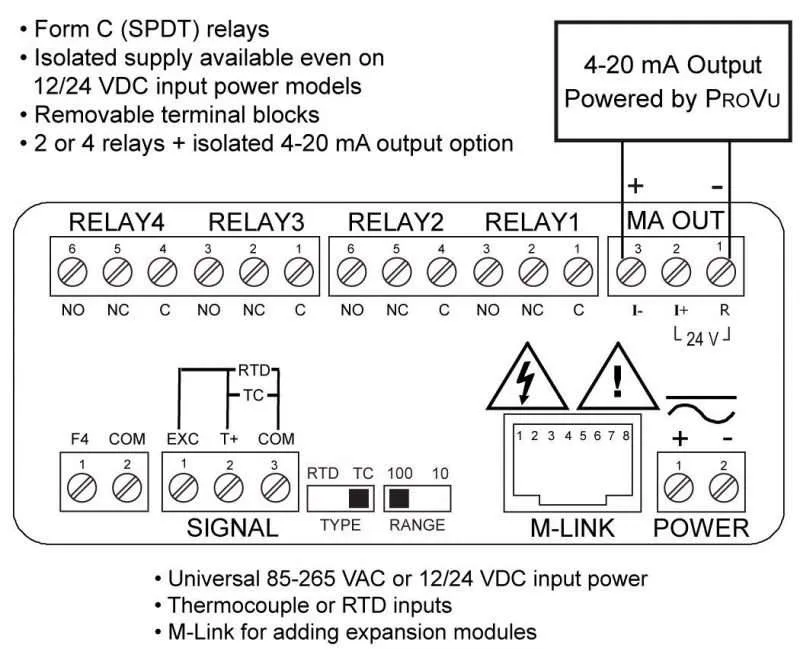

Power Options:85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max or 12-24 VDC ± 10%, 15 W max. Powered over USB for configuration only.

Normal Mode Rejection: Greater than 65 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output

Environmental:

Operating temperature range: -20 to 65°C

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Enclosure: 1/8 DIN, high impact plastic, UL 94V-0, color: black (92 mm x 45 mm). Two panel mounting bracket assemblies are provided.

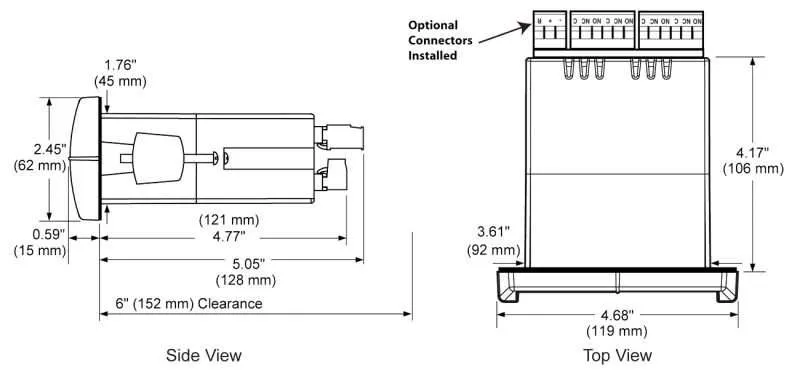

Dimensions: 4.68″ x 2.45″ x 5.64″ (119 mm x 62 mm x 143 mm) (W x H x D)

Weight: 9.5 oz (269 g)

UL File Number: UL & c-UL Listed. E160849; 508 Industrial Control Equipment.

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant

Connector Type: Micro-B receptacle

Cable: USB A Male to Micro-B Cable

Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit,

Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit

Power: USB Port

Temperature Input

Inputs: Thermocouple J, K, T, E, R, S, B, N, C; RTD 100 Ω platinum (0.00385 & 0.00392 curves), 10Ω copper, 120Ω nickel, 1000Ω platinum

Input Impedance: Greater than 100 kΩ

Offset Adjust: User programmable offset adjust ±50.0 degrees

Temperature Drift: ±2°C maximum from 0 to 65°C ambient temperature; ±4°C maximum from -20 to 0°C ambient temperature

Sensor Break: Display flashes “Open”, relays can be programmed to go “On”, “Off”, or to “Ignore” (detected as an upscale condition).

Averaging: Up to 10 RTDs connected in parallel can be averaged.

Accuracy & Range:

| Type | Range (°F) | Range (°C) | Accuracy |

| J | -200 to 2000 | -129 to 1093 | ±1°C |

| K | -200 to 2400 | -129 to 1316 | ±1°C |

| T | -200 to 752 | -129 to 400 | ±1°C |

| E | -200 to 1800 | -129 to 982 | ±1°C |

| R | -50 to 3000 | -46 to 1649 | ±2°C |

| S | -50 to 3000 | -46 to 1649 | ±2°C |

| B | 752 to 3300 | 400 to 1816 | ±2°C |

| N | -100 to 2300 | -73 to 1260 | ±2°C |

| C | 32 to 4100 | 0 to 2260 | ±2°C |

| 10 Ω | -328 to 500 | -200 to 260 | ±0.1°C |

| 100 Ω | -328 to 1562 | -200 to 850 | ±0.4°C |

| 120 Ω | -110 to 500 | -79 to 260 | ±0.1°C |

| 1000 Ω | -328 to 900 | -200 to 482 | ±0.4°C |

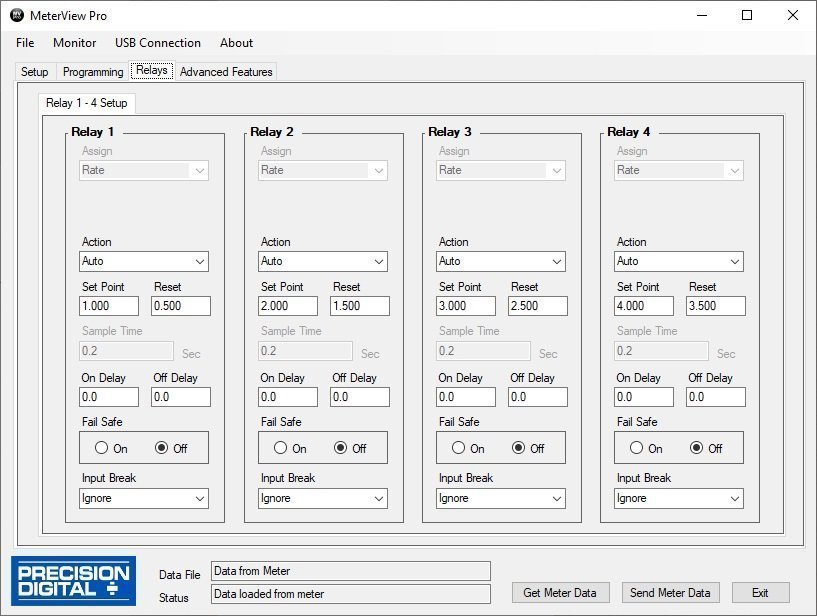

Relays

Rating: 2 or 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 watts) @ 125/250 VAC for inductive loads such as contactors, solenoids, etc.

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

Relay Operation: automatic (non-latching), latching (requires manual acknowledge), sampling (based on time), pump alternation control (2 to 8 relays), Off (disable unused relays and enable interlock feature, manual on/off control mode).

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay.

Note: Relay coil is energized in non-alarm condition. In case of power failure, relay will go to alarm state.

Auto Initialization: When power is applied to the meter, relays will reflect the state of the input to the meter.

Isolated 4-20 mA Transmitter Output

Output Source: PV (temperature), max, min, set points 1-8, manual control setting, or Modbus input

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated 4-20 mA output

Accuracy: ±0.1% of span ± 0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µA/°C max from -40 to 0°C ambient

Note: Analog output drift is separate from input drift.

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All skus rated @ 40 mA max.

External Loop Power Supply: 35 VDC maximum

Output Loop Resistance:

| Power supply | Minimum | Maximum |

| 24 VDC | 10 Ω | 700 Ω |

| 35 VDC (external) | 100 Ω | 1200 Ω |

Serial Communications

Protocol: Modbus® RTU

Meter Address/Slave ID: 1 – 247

Baud Rate: 300 – 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms or transmitter always on for RS-422 communication

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 – 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Note: Refer to the PD6000/PD7000 Modbus Register Tables for details.

Digital I/O Expansion Module

Channels: 4 digital inputs & 4 digital outputs per module

System: Up to 2 modules for a total of 8 inputs & 8 outputs

Digital Input Logic: High: 3 to 5 VDC Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC Low: 0 to 0.4 VDC

Source Current: 10 mA maximum

Sink Current: 1.5 mA minimum

+5 V Terminal: To be used as pull-up for digital inputs only.

4-Relay Expansion Module

Relays: Four Form A (SPST) rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (approx. 50 watts) @ 125/250 VAC for inductive loads

Mounting Dimensions

Notes:

- Panel cutout required: 1.772″ x 3.622″ (45mm x 92mm)

- Panel thickness: 0.040 – 0.250″ (1.0mm – 6.4mm)

- Mounting brackets lock in place for easy mounting

- Clearance: Allow 6″ (152 mm) behind the panel

Connections |

|

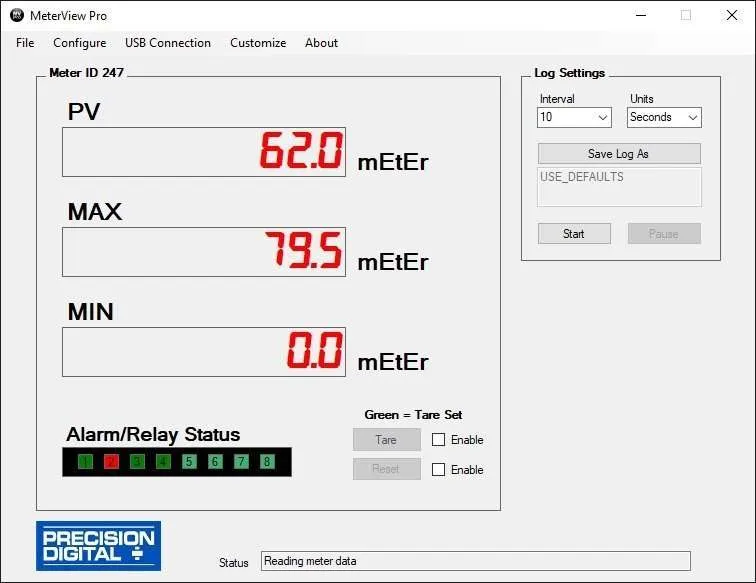

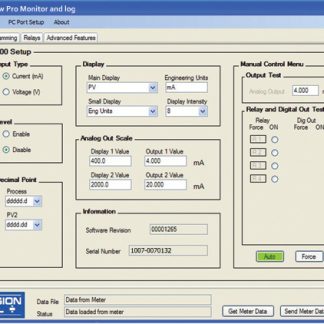

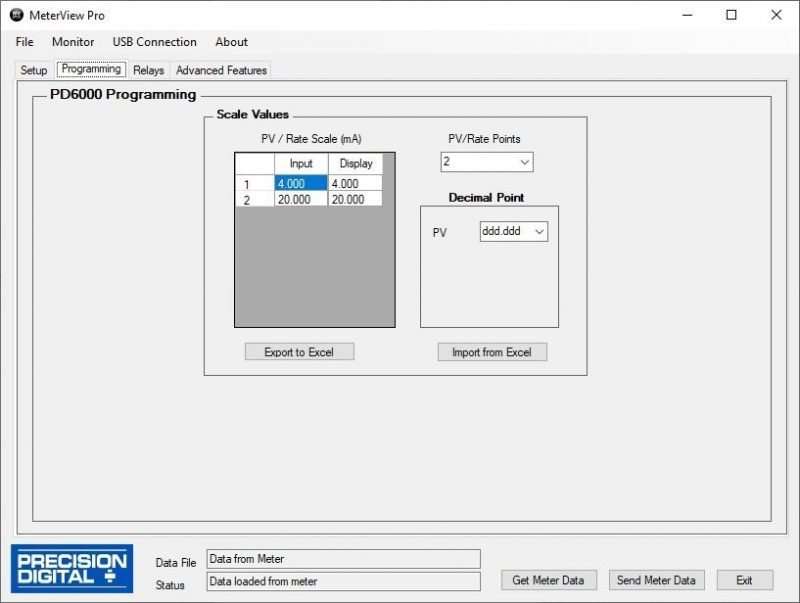

MeterView® Pro Software

MeterView® Pro software is designed for use with ProVu, ProtEX-MAX, or Helios Series meters and allows users to remotely program, monitor, and datalog using a PC. Remote programming allows for all available meter settings to be programmed through an easy, user-friendly interface. The data acquisition feature allows the user to gather readings from a meter at user-selected intervals and generate charts using common tools like Microsoft® Excel. A linearization setup function is also included. With this utility the user can configure up to 32 linearization points and upload them to the meter. All configuration data can be saved to a file for future use.

MeterView® Pro software is designed for use with ProVu, ProtEX-MAX, or Helios Series meters and allows users to remotely program, monitor, and datalog using a PC. Remote programming allows for all available meter settings to be programmed through an easy, user-friendly interface. The data acquisition feature allows the user to gather readings from a meter at user-selected intervals and generate charts using common tools like Microsoft® Excel. A linearization setup function is also included. With this utility the user can configure up to 32 linearization points and upload them to the meter. All configuration data can be saved to a file for future use.

This software is accessible via the onboard USB connection on all Helios large display meters, ProVu panel meters, and ProVu-based ProtEX-MAX explosion-proof meters produced since 6 September 2016 (firmware version 4.0 or higher). In order for meters produced prior to 6 September 2016 (firmware version 3.1 or lower) to establish digital communications with a PC, a serial communications adapter is required. For an RS-232 connection, use a PDA1232adapter.

To determine the software version of a meter:

- Go to the Diagnostics menu (

) and press Enter button.

) and press Enter button. - Press Up arrow button and scroll to Information menu (Info

).

). - Press Enter to access the software number (

), version (

), version ( ), and serial number (

), and serial number ( ) information. Write down the information as it is displayed. Continue pressing Enter until all the information is displayed.

) information. Write down the information as it is displayed. Continue pressing Enter until all the information is displayed. - The meter returns to Run Mode after displaying all the settings.

Setup

Programming

Relays