The Precision Digital Loop Leader PD6620 is a reliable flow rate and totalizer meter, perfect for tough process control tasks. Its loop-powered design means it operates efficiently without needing extra power lines. Setting up and programming the meter is easy, thanks to the four user-friendly buttons on the front panel.

This meter features a dual-line display that shows five digits on the top line and eight digits on the bottom line. It comes with preprogrammed engineering units and an optional bargraph display (model PD6624) for a clear view of your process data. You can easily switch between units of measure, such as gallons per second to liters per second, without having to re-scale the meter.

The display can be tailored to meet your specific needs. Typically, the top line shows the flow rate, while the bottom line can display the total, grand total, or engineering units. With three programmable function keys and a digital input, you can customize the meter for specialized applications.

Every model includes two open collector outputs and can be equipped with two solid-state relays and a 4-20 mA analog output. These outputs are versatile and can be programmed for various functions, including alarm notifications, signal retransmission, and pump control.

Thanks to its loop-powered feature, the Loop Leader PD6620 eliminates the need for expensive power installations. It is housed in a shallow-depth case with an IP65 rating, ensuring durability in various environments. The meter operates effectively in a wide temperature range from -40 to 167°F (-40 to 75°C). Whether used indoors or outdoors, in bright sunlight or dim conditions, and in wet or dirty environments, the Loop Leader is built to perform anywhere.

Specifications

Except where noted all specifications apply to operation at +25°C.

Input

Input: 4-20 mA

Accuracy: ±0.02% of span ±1 count, Square root and programmable exponent: 10-100% FS

Voltage Drop: Without backlight: 1.5 V maximum,

With backlight: 4.7 V maximum

Equivalent Resistance: With backlight off: 75 Ω @ 20 mA

With backlight on: 225 Ω @ 20 mA

Input Overload: Over current protection to 1 A maximum

Temperature Drift: 25 PPM/°C from -40 to 75°C ambient

Function: Linear, square root, or programmable exponent

Low-Flow Cutoff: 0.0 to 999,999.9

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

Display

Display: Dual-line LCD with backlight. Both lines 14-segment alphanumeric. Top: 0.7″ (17.8 mm), Bottom: 0.4″ (10.2 mm). Display may be programmed to turn red and flash a user-defined message on alarm condition.

Backlight: Powered by 4-20 mA loop. Intensity varies with signal level

PD6622 & PD6626:

Top line: 5 digits (-9999 to 99999) or 5 characters (all capital & most lower case letters)

Bottom line: 8 digits (-9,999,999 to 99,999,999; separated by commas) or 8 characters (all capital & most lower case letters)

PD6624 & PD6628:

Top line: 5 digits (-9999 to 99999) or 5 characters (all capital & most lower case letters)

Bottom line: 8 digits (-9,999,999 to 99,999,999; separated by commas) or 8 characters (all capital & most lower case letters)

Bargraph: 20 segments, numeric percent indication at top

Decimal Point & Commas

Top line: Up to four decimal places

Bottom line: Up to seven decimal places and commas to indicate 1000s (i.e. 88,987,628)

Dual-Scale Feature: The input can be displayed in different scales on the top and bottom lines. For instance, the top line could display the flow in GPM and the bottom line could display that same input in CFM.

Alarm Indication: Red backlight, flashing display, alarm symbol (!); Symbols are not available on bargraph skus.

Alarm Message: On or Off; user programmable, 8 characters maximum. Displayed every 10 seconds for 1 second on bottom line.

Display Update Rate: Ambient > -10°C: 1 update/second

Ambient -20°C: 1 update/2 seconds

From -20°C to -40°C the update rate slows down 1 second for every -2°C (e.g. at -24°C, 1 update/4 seconds).

Overrange: Top: 99999; Bottom: 99,999,999 (flashing)

Underrange: Top: -9999; Bottom: -9,999,999 (flashing)

General

Environmental: Operating temperature range:

-40 to 75°C for safe area products

-40 to 70°C for hazardous area products

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing. Printed circuit boards are conformally coated.

Programming Method: Front panel & Free PC-based USB programming software

Enclosure & Materials: Enclosure: 1/8 DIN, IP65, NEMA 4X front panel, high impact plastic, NORYL® polyphenylene ether & polystyrene blend (PPE PS) resin, UL 94V-0, Color: gray, Gasket: silicone rubber, Faceplate: LEXAN® polycarbonate (PC) film, Buttons: silicone rubber

Noise Filter: Averages the input signal over a period of time between 1 and 16 seconds to dampen the effects of a noisy signal that causes a jumpy display.

Recalibration: Recalibration is recommended at least every 12 months.

Max/Min Display: Max/min readings reached by the process are stored until reset by the user or until power to the meter is turned off.

Password: There are three password types available: Main, Total, and Grand Total. The Main password prevents access to the meter Programming Mode. Total and Grand Total passwords prevent resetting the total and grand total, respectively.

Non-Volatile Memory: All programmed settings and total and grand total values are stored in non-volatile memory for a minimum of ten years if power is lost.

Normal Mode Rejection: 64 dB at 50/60 Hz

Connections: Removable screw terminals accept 12 to 22 AWG.

DI Digital Input Contacts: 2.1 VDC on contact. Connect normally open contacts across DI+ and DI

DI Digital Input Logic Levels: Logic High: 2.4 to 30 VDC (max)

Logic Low: 0 to 0.9 VDC

Tightening Torque: Screw terminal connectors: 4.5 lb-in (0.5 Nm)

Mounting screws: 8.0 lb-in max. (0.9 Nm)

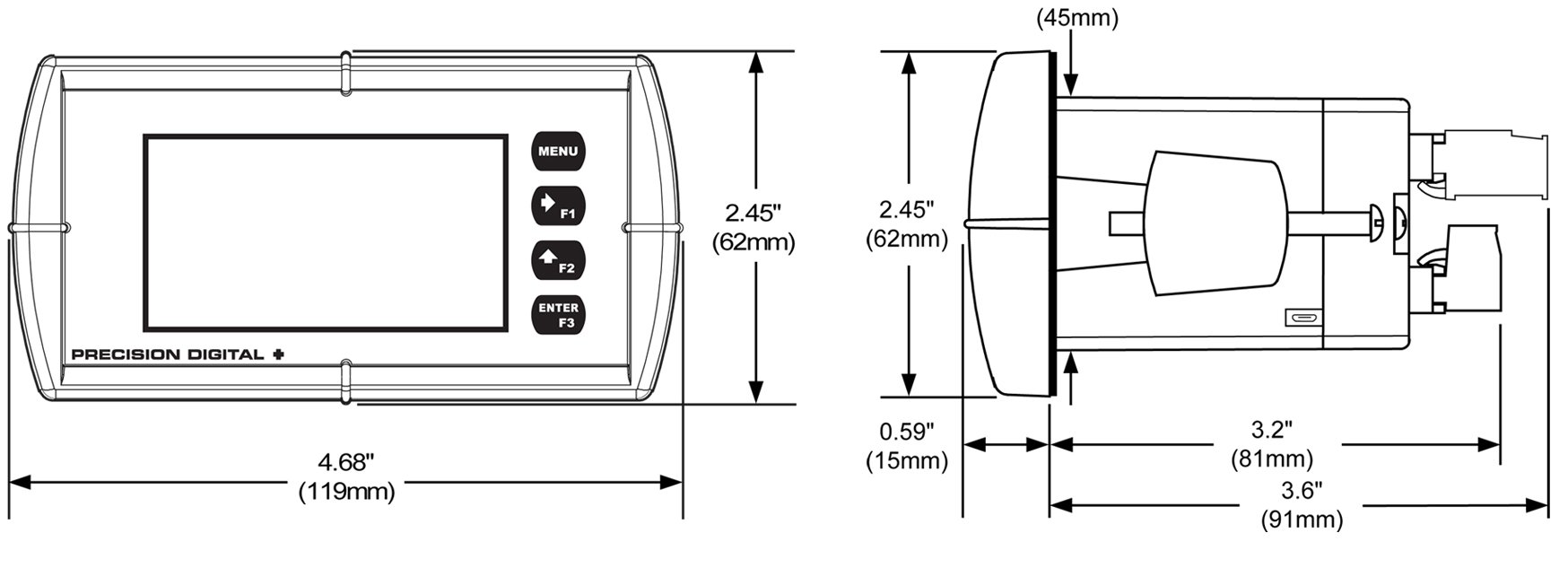

Overall Dimensions: 4.68″x 2.45″x 3.79″ (119 mm x 62 mm x 96 mm) (W x H x D)

Weight: 8.7 oz (247g) with option board

Warranty: 3 years parts and labor

Rate/Totalizer

Rate Display Capability: Top display: -9999 to 99999; bottom display: -9,999,999 to 99,999,999 (with commas)

Total Display Capability: Top display: -9999 to 99999; bottom display -9,999,999 to 99,999,999 (with commas)

Grand Total Display Capability: Top display: N/A; bottom display -9,999,999 to 99,999,999 (with commas)

13-Digit Total & Grand Total Capability: Up to 9,999,999,999,999 using both lines with 13-digit total feature enabled.

Total & Grand Total Indication: On bottom display; “T” indicates total and “GT” indicates grand total. (not available on bargraph skus)

Total Decimal Point: Up to four decimal places on top, up to seven decimal places on bottom. Total decimal point is independent of rate decimal point.

Totalizer: Calculates total based on rate and rate units to display total in engineering units. A custom factor must be programmed if using custom defined units.

Time Base: Seconds, Minutes, Hours, Days

Totalizer Rollover: Totalizer rolls over when display exceeds 99,999,999 (9,999,999,999,999 if 13-digit limit enabled). Relay status reflects display.

Total & Grand Total Reset: Via front panel button or external contact closure on digital input

Total & Grand Total Reset Passwords: Total and grand total passwords may be entered to prevent resetting the total or grand total unless a password is entered.

Non-Resettable Grand Total: Grand total reset may be disabled through the meter interface. Grand total reset may be permanently disabled by selecting YES at the PERMLOCK menu.

Caution: Once the Grand Total has been programmed as “non-resettable” the feature cannot be disabled

Common Open Collector & Relay (Alarm) Specifications

High or Low Alarm: User programmable for high or low alarm

Alarm Deadband: 0-100% FS, user programmable

On & Off Time Delay: 0 to 9,999 seconds

Fail-Safe Operation: Independent for each open collector and relay

Alarm Operation: Automatic, Automatic with manual override, Latching (manual reset anytime), Latching with reset after cleared (manual reset only after alarm has cleared)

Alarm Indication: Red backlight, flashing display, alarm symbol (!) (symbols not available on bargraph skus)

Alarm Message: On or Off; User programmable, 8 characters maximum. Displayed every 10 seconds for 1 second on bottom line

Alarm Acknowledge: Front panel ACK button or external digital input resets output and screen indication

Auto Initialization: When power is applied to the meter, open collectors and relays will reflect the state of the input to the meter.

Timer Output: One-shot or Continuous

Off Time Delay: 1 sec to 99:59:59 (hrs:min:sec)

On Time: 1 sec to 99:59:59 (hrs:min:sec)

Stopwatch: Output turns on when started and off when stopped

Open Collector Outputs

Rating: Two NPN, Isolated open collector, 30 VDC @ 150 mA max

Output Assignment: Pulse, Alarm, Timer, Total Reset, Stopwatch on/off, or Disable

Pulse Output Source: Rate, Total, Grand Total, or Test Frequency

Pulse Output Factor: 0.000001 to 999,999.9

Pulse Width: 0.5 ms @ 1 kHz; 500 ms @ 1 Hz; 50% duty cycle

Pulse Output Frequency: 1,000 Hz maximum

Quadrature Pulse Output: Available for Output 2 (90° behind Output 1)

Alarm Output Source: Assign to Rate, Total, Grand Total or Digital Input

Solid State Relays

Rating: Resistive Load: 250 VAC/DC @ 1 A

Inductive Load: 75 VA @ 0.6 A, 250 VAC/DC max (Safe Area only)

Noise Suppression: Metal oxide varistors across outputs

Relay Assignment: Alarm, Sample, Timer, Batch, Stopwatch on/off, or Disable

Alarm Output Source: Assign to Rate, Total, Grand Total, or Digital Input

4-20 mA Transmitter Output

Accuracy: ±0.05% FS ±0.001mA

Output Source: Rate, total, re-transmit; reverse scaling allowed

Scaling Range: 1.00 to 23.0 mA

Disable: High impedance state, less than 1 mA

Calibration: Factory calibrated 4.00 to 20.00 mA

Underrange: 1.0 mA, 3.5 mA, or 3.8 mA (If input < 3.5 mA), or Off; user selectable

Overrange: 20.5 mA, 20.8 mA, or 23.0 mA (If input > 20.5 mA), or Off; user selectable

Isolation: 500 V input-to-output

Temperature Drift: 0.5 μA/°C max from -40 to 75°C ambient

External Loop Power Supply: 7.0 VDC to 30.0 VDC maximum

Output Loop Resistance: 10-750 Ω @ 24 VDC; 100-1100 Ω @ 30 VDC

Batch Control

Methods: Automatic or Manual, count up or count down

Manual Batch Start: Pressing F1 function key starts the batch

Manual Batch Pause/Stop: Pressing F3 once pauses the batch, pressing it twice cancels the batch

Automatic Batching: The Loop Leader can be used as an automatic batch controller where batches run continuously without operator input.

Batching Relay Operation: Single or dual-relay batching with optional preclose for dual-stage operation

Batch Preset: Set via F2 function key anywhere between 0.0001 to 99,999 based on batch total decimal point. If batch total is assigned to bottom, the preset can be up to 8 digits.

Batch Preclose: For two-stage batch application, a preclose value can be set to close the main flow line.

Automatic Batch Restart Delay: 1 to 9,999 seconds. The batch will automatically restart after completion of the last batch.

Free Meterview XL PC-Based Programming Software

The main screen displays an image of the connected meter and includes various information about this meter, such as sku number, readings, and status.

Free, PC-based, MeterView XL software that connects to the meter via a micro USB cable is available for programming and setup of the meters. This software greatly simplifies the programming process and also allows the user to save configuration files for later use. The meter will also be powered by the USB connection so no additional power is needed during programming.

- Free

- Easiest Way to Program Your Loop Leader

- Convenient USB Connection

- Meter Powered by USB Connection During Programming

- Save & Print Configuration Files without Meter Connected

- Micro USB Cable Provided

Mounting Dimensions

Notes:

Notes:

- Panel cutout required: 1.772″ x 3.622″ (45mm x 92mm)

- Panel thickness: 0.040 – 0.250″ (1.0mm – 6.4mm)

- Mounting brackets lock in place for easy mounting

- Clearance: Allow 6″ (152 mm) behind the panel

Applications

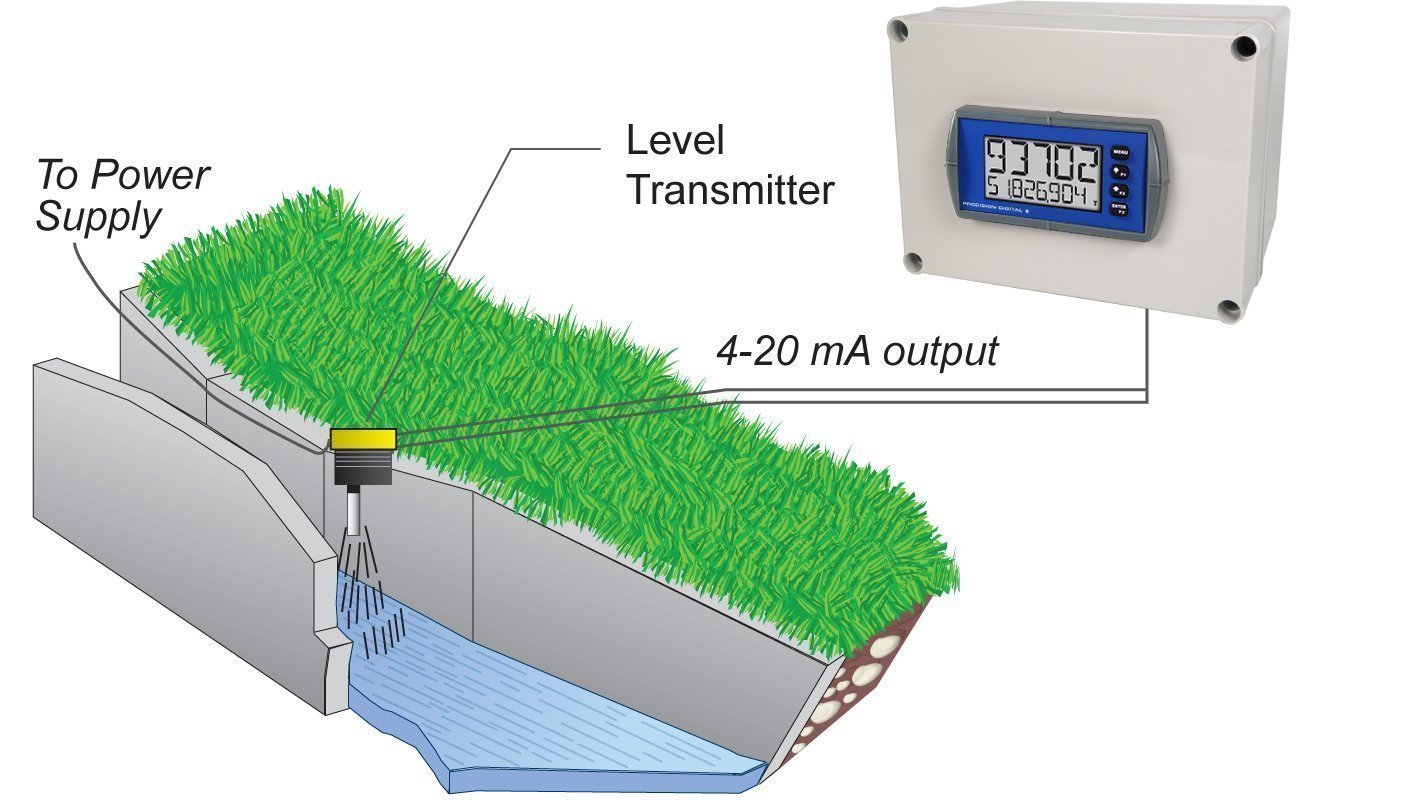

Open Channel Flow

The PD6622/24, in combination with an ultrasonic level transmitter, makes for an economical way to measure and display open channel flow rate and total in most weirs and flumes and take periodic samples.

Differential Pressure Flow

The PD6622/24 can display flow rate and total by extracting the square root from the 4-20 mA signal from a differential pressure transmitter. The user selectable low-flow cutoff feature gives a reading of zero when the flow rate drops below a user selectable value.

- Display Flow Rate

- User Selectable Low-Flow Cutoff

- Only 2 Calibration Points Required

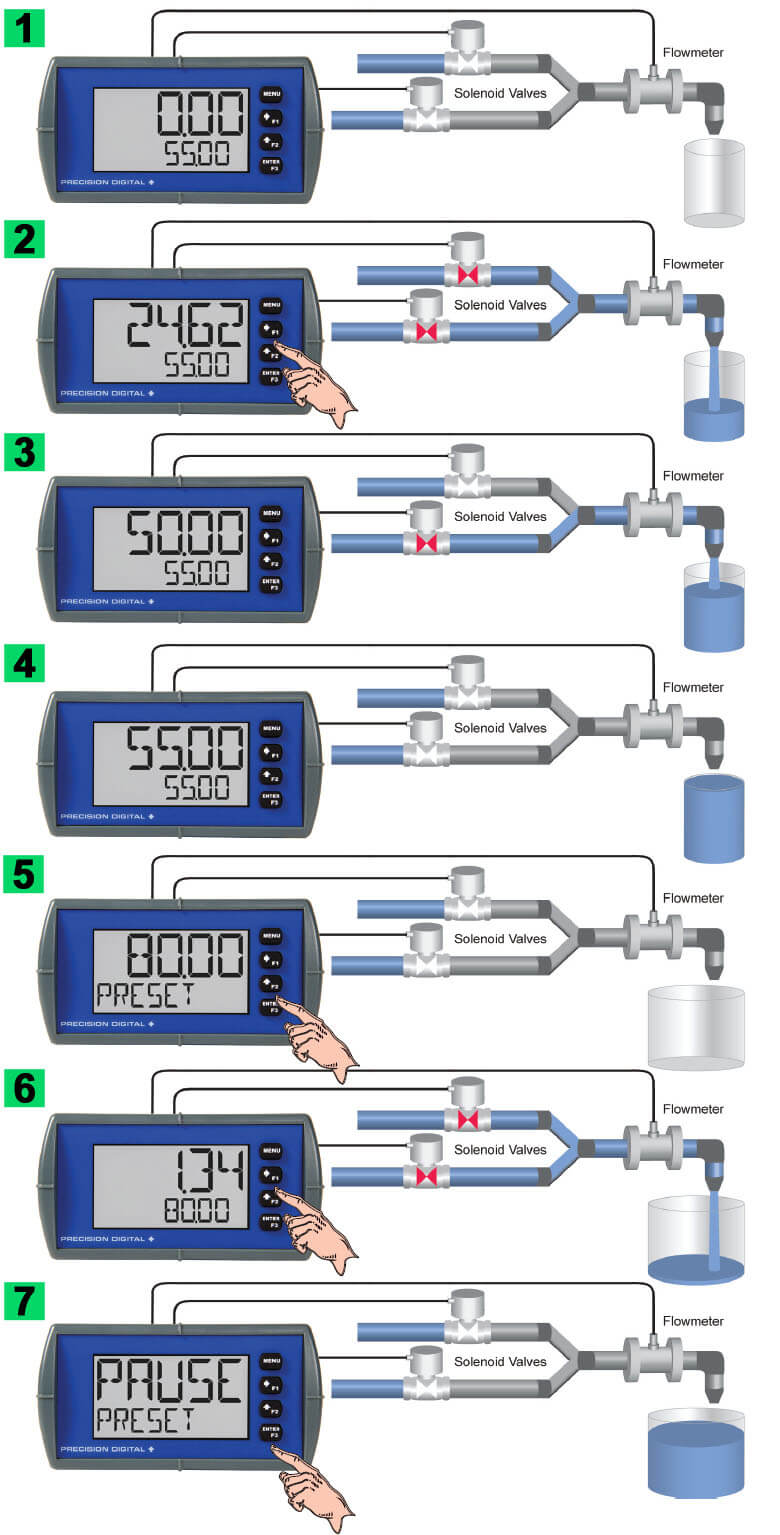

Batch Control

The Loop Leader, when ordered with the two solid state relays, can be used as a simple, one or two-stage batch controller. The user enters a preset and preclose value and sets the Loop Leader to either count up or count down. The top display will show the total and the bottom display will show the preset batch amount. The function keys are automatically changed so that F1 starts a batch, F2 opens the preset menu to allow the preset value to be changed, and F3 pauses/stops the currently running batch. Batching can be either automatic or manual.

The following shows the Loop Leader performing a manual batch operation:

System Setup

Both valves are closed with an empty barrel in place. The batched total is displayed in the top display, the preset is selected for the bottom display.

Batch Start

The START button (F1) is pressed. Both valves open. The barrel begins to fill.

Preclose Valve

When the batch total reaches a value of 50.00 (Preset [55.00] – Preclose [5.00]) the full-flow valve closes. The fill rate of the tank slows as a result.

Completed Batch

When the batch total equals the preset amount, the restricted flow valve closes. The barrel is now full.

Change Preset

After placing a new, empty barrel, a new preset fill amount may be selected with the Batch key (F2), while the process is stopped.

Begin New Batch

Press the START key (F1) and a new batch will begin. With both valves open, the process continues.

Pause/Stop

At any time, the STOP button (F3) may be pressed, once to Pause the process, or twice to cancel the batch, which stops the process.

Timer Function

Application Timers are used in everyday life; one of the most common examples is the microwave oven. Industrial timers are used in process control applications where certain events or actions need to be controlled by time. Examples include automatic and batch control applications, where the relay needs to be energized for a specific length of time.

The timer function is available on the open collector and relay outputs; which means that you can have up to four timers per meter. The start and stop actions can be triggered from the setup menu or by the function keys and digital input. The meter can be setup to display the off/on timer count down.

There are two modes of operation:

- Continuous Timer (Interval)

At the start of the timer the output is off and turns on after the Off Delay elapses. The output remains on for the duration of the On Time. The cycle repeats until the user stops the timer either from the menu or a function key. - One-Shot Timer

At the start of the timer the output is off and turns on after the Off Delay elapses. The output remains on for the duration of the On Time. The timer stops and the cycle does not repeat.

- A sensor detects the bottle is in place and triggers the digital input to start the timer

- The timer output controls the filling pump

- The On Time is set according to the time needed to fill the bottle

Connections

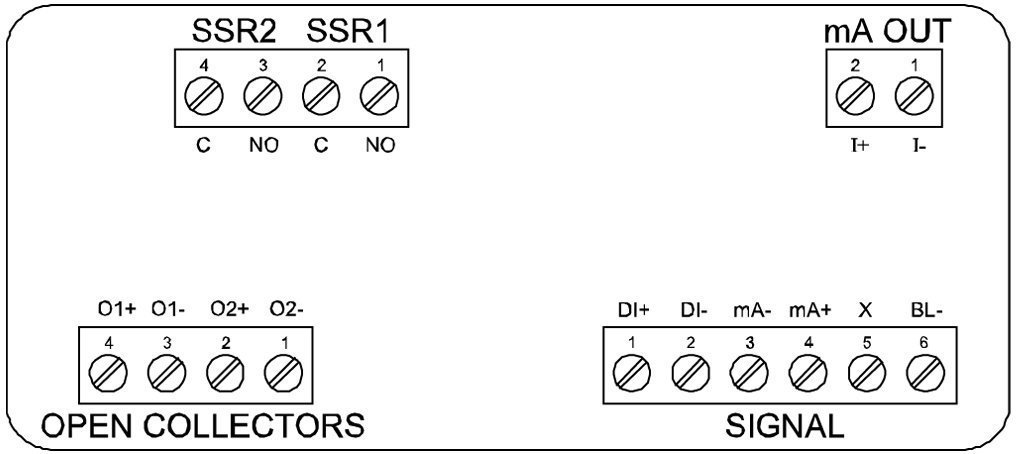

Connectors Labeling

The connectors’ label, affixed to the meter, shows the location of all connectors available with requested configuration.

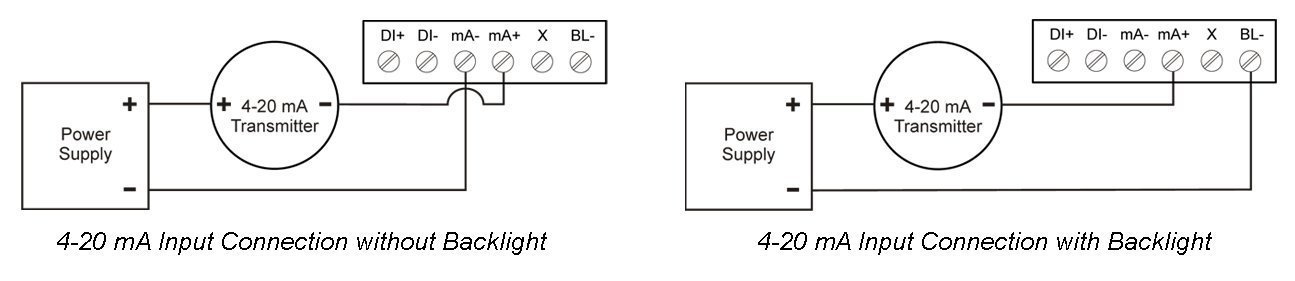

Current Loop (4-20 mA) Connections

The following figures show a 4-20 mA current loop connected to the meter. The first figure shows the connection with the backlight disabled and the second shows the connection with the backlight enabled. The meter is powered by the 4-20 mA current loop.

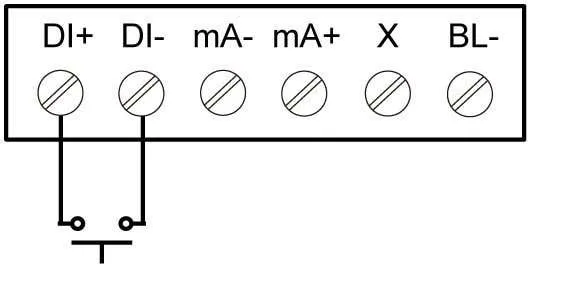

Digital Input Connection

A digital input is standard on the meter. This digital input is connected with a normally open contact across DI+ and DI-, or with an active low signal applied to DI+.

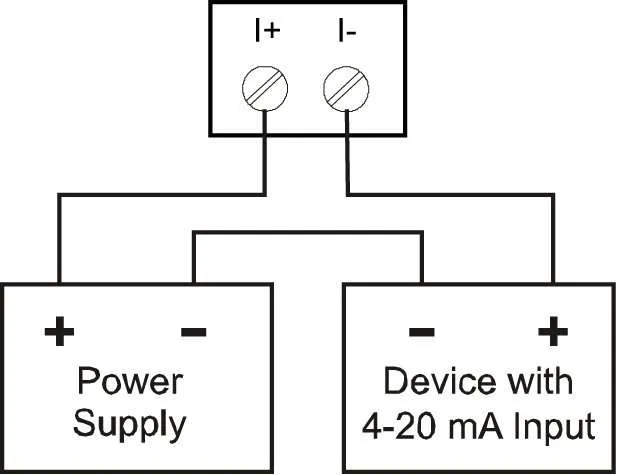

4-20 mA Output Connections

Connections for the 4-20 mA transmitter output are made to the connector terminals labeled MA OUT. The 4-20 mA output must be powered from an external power supply.

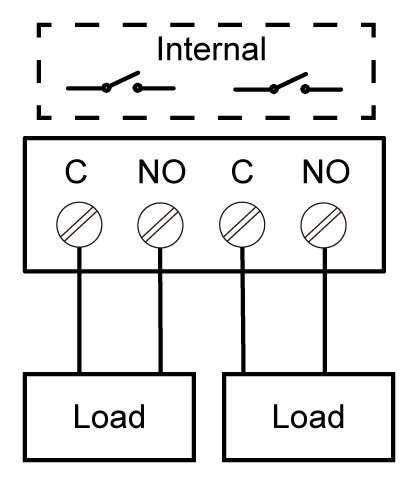

Relay Connections

Relay connections are made to two four-terminal connectors. Each relay’s C terminal is common only to the normally open (NO) contact of the corresponding relay.

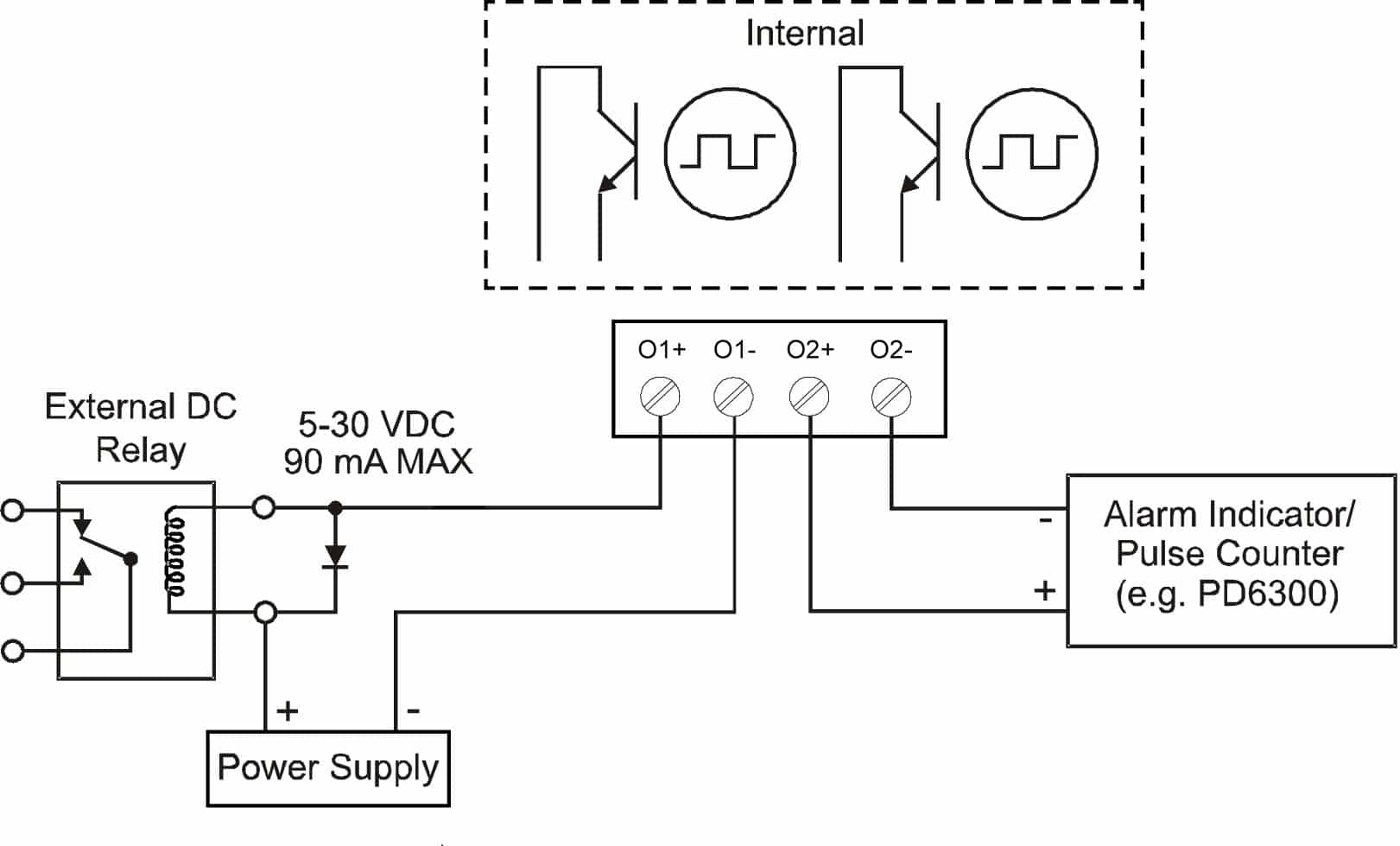

Open Collector Outputs

Open collector output 1 and 2 connections are made to terminals labeled O1+ and O1-, and O2+ and O2-. Connect the alarm or pulse input device as shown below.