The Precision Digital PD6620 is a dependable and adaptable instrument designed for monitoring flow rates and totals in various industrial settings. Its intrinsically safe and non-incendive design allows for easy installation in any location, providing detailed data from a 4-20 mA signal.

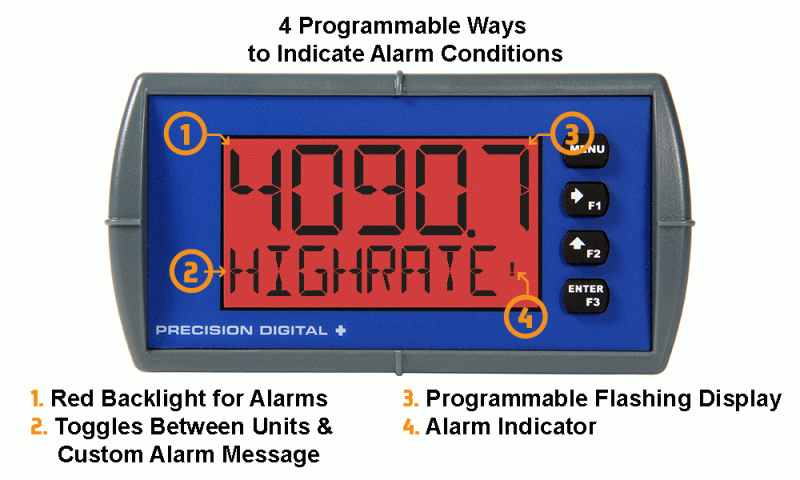

One of the key highlights of the PD6620 is its dual display capability. The top line features a 5-digit alphanumeric display that typically shows the flow rate, while the bottom line has an 8-digit alphanumeric display for the total or grand total. Both lines use clear 14-segment characters, making it easy to read tags, units, or alarm messages. Additionally, the PD6624/6 models come with a 20-segment bar graph that visually indicates the percentage along with a numeric value.

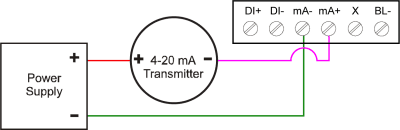

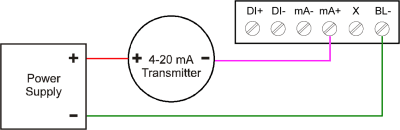

Installing the PD6620 is straightforward since it draws power from the 4-20 mA loop, eliminating the need for an external power source. It has a minimal voltage drop of just 1.5 V (4.7 V with backlight), ensuring it does not significantly impact the loop. The device features a robust NEMA 4X, IP65 front panel, making it suitable for a wide range of environments, with an operating temperature range of -40 to 158°F (-40 to 70°C). The conformally coated PCBs enhance durability, and the backlit LCD ensures readability in both bright and dim conditions. Furthermore, the PD6620 is designed to be intrinsically safe and non-incendive, making it ideal for hazardous locations.

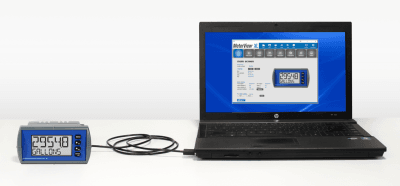

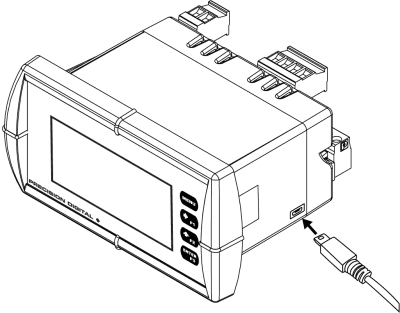

For easy programming and setup, users can connect the meter to a PC using a micro USB cable and the included software. Alternatively, programming and operation can be done directly on the device using the four front panel buttons, three of which can be customized as function keys. The PD6620 also features a digital input, which is useful for remotely resetting the total or controlling timer and batch start/stop functions.

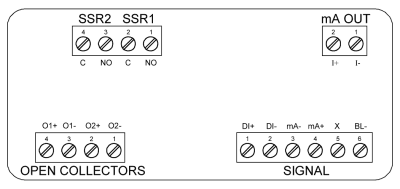

This instrument offers versatile output options, including two open collector outputs, two solid-state relays, and a 4-20 mA analog output. The open collector outputs can be utilized for alarm notifications or to send pulses when a specific total is reached. The relays can be programmed for alarm indications, on/off control, sampling, or simple batch control, adding to the instrument’s versatility.

Discover the reliability and ease of use of the Precision Digital PD6620, equipped with advanced features and comprehensive functionality, perfect for monitoring flow rates and totals in industrial applications.

Specifications

Except where noted all specifications apply to operation at +25°C.

Input

Input: 4-20 mA

Accuracy: ±0.02% of span ±1 count, Square root and programmable exponent: 10-100% FS

Voltage Drop: Without backlight: 1.5 V maximum,

With backlight: 4.7 V maximum

Equivalent Resistance: With backlight off: 75 Ω @ 20 mA

With backlight on: 225 Ω @ 20 mA

Input Overload: Over current protection to 1 A maximum

Temperature Drift: 25 PPM/°C from -40 to 75°C ambient

Function: Linear, square root, or programmable exponent

Low-Flow Cutoff: 0.0 to 999,999.9

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

Display

Display: Dual-line LCD with backlight. Both lines 14-segment alphanumeric. Top: 0.7″ (17.8 mm), Bottom: 0.4″ (10.2 mm). Display may be programmed to turn red and flash a user-defined message on alarm condition.

Backlight: Powered by 4-20 mA loop. Intensity varies with signal level

PD6622 & PD6626:

Top line: 5 digits (-9999 to 99999) or 5 characters (all capital & most lower case letters)

Bottom line: 8 digits (-9,999,999 to 99,999,999; separated by commas) or 8 characters (all capital & most lower case letters)

PD6624 & PD6628:

Top line: 5 digits (-9999 to 99999) or 5 characters (all capital & most lower case letters)

Bottom line: 8 digits (-9,999,999 to 99,999,999; separated by commas) or 8 characters (all capital & most lower case letters)

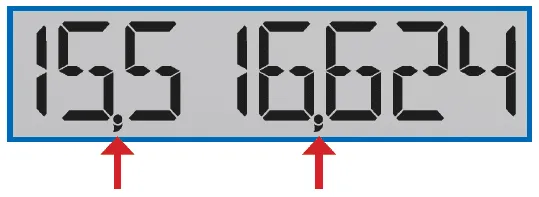

Bargraph: 20 segments, numeric percent indication at top

Decimal Point & Commas

Top line: Up to four decimal places

Bottom line: Up to seven decimal places and commas to indicate 1000s (i.e. 88,987,628)

Dual-Scale Feature: The input can be displayed in different scales on the top and bottom lines. For instance, the top line could display the flow in GPM and the bottom line could display that same input in CFM.

Alarm Indication: Red backlight, flashing display, alarm symbol (!); Symbols are not available on bargraph skus.

Alarm Message: On or Off; user programmable, 8 characters maximum. Displayed every 10 seconds for 1 second on bottom line.

Display Update Rate: Ambient > -10°C: 1 update/second

Ambient -20°C: 1 update/2 seconds

From -20°C to -40°C the update rate slows down 1 second for every -2°C (e.g. at -24°C, 1 update/4 seconds).

Overrange: Top: 99999; Bottom: 99,999,999 (flashing)

Underrange: Top: -9999; Bottom: -9,999,999 (flashing)

General

Environmental: Operating temperature range:

-40 to 75°C for safe area products

-40 to 70°C for hazardous area products

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing. Printed circuit boards are conformally coated.

Programming Method: Front panel & Free PC-based USB programming software

Enclosure & Materials: Enclosure: 1/8 DIN, IP65, NEMA 4X front panel, high impact plastic, NORYL® polyphenylene ether & polystyrene blend (PPE PS) resin, UL 94V-0, Color: gray, Gasket: silicone rubber, Faceplate: LEXAN® polycarbonate (PC) film, Buttons: silicone rubber

Noise Filter: Averages the input signal over a period of time between 1 and 16 seconds to dampen the effects of a noisy signal that causes a jumpy display.

Recalibration: Recalibration is recommended at least every 12 months.

Max/Min Display: Max/min readings reached by the process are stored until reset by the user or until power to the meter is turned off.

Password: There are three password types available: Main, Total, and Grand Total. The Main password prevents access to the meter Programming Mode. Total and Grand Total passwords prevent resetting the total and grand total, respectively.

Non-Volatile Memory: All programmed settings and total and grand total values are stored in non-volatile memory for a minimum of ten years if power is lost.

Normal Mode Rejection: 64 dB at 50/60 Hz

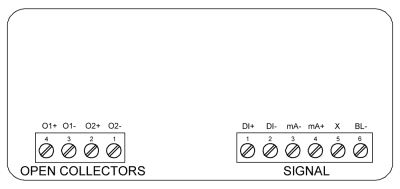

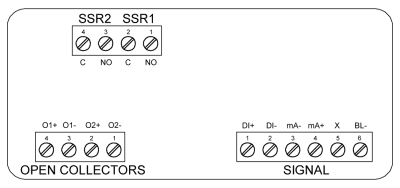

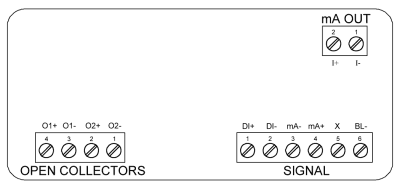

Connections: Removable screw terminals accept 12 to 22 AWG.

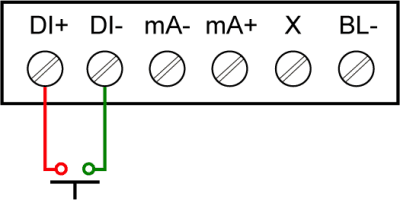

DI Digital Input Contacts: 2.1 VDC on contact. Connect normally open contacts across DI+ and DI

DI Digital Input Logic Levels: Logic High: 2.4 to 30 VDC (max)

Logic Low: 0 to 0.9 VDC

Tightening Torque: Screw terminal connectors: 4.5 lb-in (0.5 Nm)

Mounting screws: 8.0 lb-in max. (0.9 Nm)

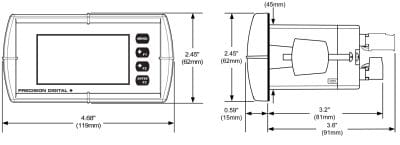

Overall Dimensions: 4.68″x 2.45″x 3.79″ (119 mm x 62 mm x 96 mm) (W x H x D)

Weight: 8.7 oz (247g) with option board

Warranty: 3 years parts and labor

Rate/Totalizer

Rate Display Capability: Top display: -9999 to 99999; bottom display: -9,999,999 to 99,999,999 (with commas)

Total Display Capability: Top display: -9999 to 99999; bottom display -9,999,999 to 99,999,999 (with commas)

Grand Total Display Capability: Top display: N/A; bottom display -9,999,999 to 99,999,999 (with commas)

13-Digit Total & Grand Total Capability: Up to 9,999,999,999,999 using both lines with 13-digit total feature enabled.

Total & Grand Total Indication: On bottom display; “T” indicates total and “GT” indicates grand total. (not available on bargraph skus)

Total Decimal Point: Up to four decimal places on top, up to seven decimal places on bottom. Total decimal point is independent of rate decimal point.

Totalizer: Calculates total based on rate and rate units to display total in engineering units. A custom factor must be programmed if using custom defined units.

Time Base: Seconds, Minutes, Hours, Days

Totalizer Rollover: Totalizer rolls over when display exceeds 99,999,999 (9,999,999,999,999 if 13-digit limit enabled). Relay status reflects display.

Total & Grand Total Reset: Via front panel button or external contact closure on digital input

Total & Grand Total Reset Passwords: Total and grand total passwords may be entered to prevent resetting the total or grand total unless a password is entered.

Non-Resettable Grand Total: Grand total reset may be disabled through the meter interface. Grand total reset may be permanently disabled by selecting YES at the PERMLOCK menu.

Caution: Once the Grand Total has been programmed as “non-resettable” the feature cannot be disabled

Common Open Collector & Relay (Alarm) Specifications

High or Low Alarm: User programmable for high or low alarm

Alarm Deadband: 0-100% FS, user programmable

On & Off Time Delay: 0 to 9,999 seconds

Fail-Safe Operation: Independent for each open collector and relay

Alarm Operation: Automatic, Automatic with manual override, Latching (manual reset anytime), Latching with reset after cleared (manual reset only after alarm has cleared)

Alarm Indication: Red backlight, flashing display, alarm symbol (!) (symbols not available on bargraph skus)

Alarm Message: On or Off; User programmable, 8 characters maximum. Displayed every 10 seconds for 1 second on bottom line

Alarm Acknowledge: Front panel ACK button or external digital input resets output and screen indication

Auto Initialization: When power is applied to the meter, open collectors and relays will reflect the state of the input to the meter.

Timer Output: One-shot or Continuous

Off Time Delay: 1 sec to 99:59:59 (hrs:min:sec)

On Time: 1 sec to 99:59:59 (hrs:min:sec)

Stopwatch: Output turns on when started and off when stopped

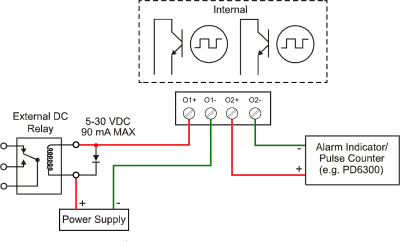

Open Collector Outputs

Rating: Two NPN, Isolated open collector, 30 VDC @ 150 mA max

Output Assignment: Pulse, Alarm, Timer, Total Reset, Stopwatch on/off, or Disable

Pulse Output Source: Rate, Total, Grand Total, or Test Frequency

Pulse Output Factor: 0.000001 to 999,999.9

Pulse Width: 0.5 ms @ 1 kHz; 500 ms @ 1 Hz; 50% duty cycle

Pulse Output Frequency: 1,000 Hz maximum

Quadrature Pulse Output: Available for Output 2 (90° behind Output 1)

Alarm Output Source: Assign to Rate, Total, Grand Total or Digital Input

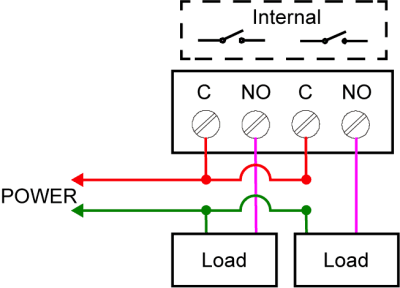

Solid State Relays

Rating: Resistive Load: 250 VAC/DC @ 1 A

Inductive Load: 75 VA @ 0.6 A, 250 VAC/DC max (Safe Area only)

Noise Suppression: Metal oxide varistors across outputs

Relay Assignment: Alarm, Sample, Timer, Batch, Stopwatch on/off, or Disable

Alarm Output Source: Assign to Rate, Total, Grand Total, or Digital Input

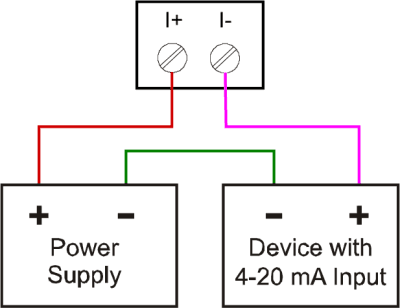

4-20 mA Transmitter Output

Accuracy: ±0.05% FS ±0.001mA

Output Source: Rate, total, re-transmit; reverse scaling allowed

Scaling Range: 1.00 to 23.0 mA

Disable: High impedance state, less than 1 mA

Calibration: Factory calibrated 4.00 to 20.00 mA

Underrange: 1.0 mA, 3.5 mA, or 3.8 mA (If input < 3.5 mA), or Off; user selectable

Overrange: 20.5 mA, 20.8 mA, or 23.0 mA (If input > 20.5 mA), or Off; user selectable

Isolation: 500 V input-to-output

Temperature Drift: 0.5 μA/°C max from -40 to 75°C ambient

External Loop Power Supply: 7.0 VDC to 30.0 VDC maximum

Output Loop Resistance: 10-750 Ω @ 24 VDC; 100-1100 Ω @ 30 VDC

Batch Control

Methods: Automatic or Manual, count up or count down

Manual Batch Start: Pressing F1 function key starts the batch

Manual Batch Pause/Stop: Pressing F3 once pauses the batch, pressing it twice cancels the batch

Automatic Batching: The Loop Leader can be used as an automatic batch controller where batches run continuously without operator input.

Batching Relay Operation: Single or dual-relay batching with optional preclose for dual-stage operation

Batch Preset: Set via F2 function key anywhere between 0.0001 to 99,999 based on batch total decimal point. If batch total is assigned to bottom, the preset can be up to 8 digits.

Batch Preclose: For two-stage batch application, a preclose value can be set to close the main flow line.

Automatic Batch Restart Delay: 1 to 9,999 seconds. The batch will automatically restart after completion of the last batch.

Hazardous Area Approvals

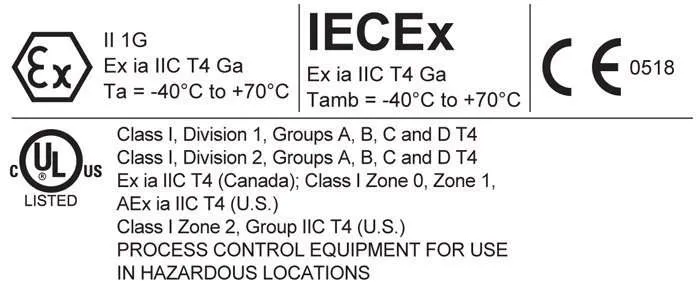

ATEX: II 1G, Ex ia IIC T4 Ga, Ta = -40°C to +70°C

Certificate number: CML 17ATEX2015X

IECEx: Ex ia IIC T4 Ga, Tamb = -40°C to +70°C

Certificate number: IECEx CML 17.0008X

UL & C-UL Listed as Intrinsically Safe and Nonincendive:

Class I, Division 1, Groups A, B, C and D T4,

Class I, Division 2, Groups A, B, C and D T4

Ex ia IIC T4 (Canada); Class I Zone 0, Zone 1

AEx ia IIC T4 (U.S.)

Class I Zone 2, Group IIC T4 (U.S.)

PROCESS CONTROL EQUIPMENT FOR USE IN HAZARDOUS LOCATIONS

UL & C-UL 61010 Listed for Electrical Safety and Type 4X Environmental:

Standards for Safety:

IEC 61010-1:2010 (3rd Edition);

UL 61010-1, 3rd Edition;

CAN/CSA-C22.2 No. 61010-1-12, 3rd Edition;

Additional Standards:

UL 50E