Precision Digital PD6210 is a 1/8 DIN analog input (4-20 mA, 0-5 V, 1-5 V, etc.) digital batch controller specifically designed for single and multi-stage batching applications. It provides excellent but straightforward batch control capabilities with features such as pre-close relays and automatic overrun correction for more accurate batches and intuitive front panel buttons for simple operation and menu navigation. The pre-close deactivates a specific relay on the batch controller before the batch is complete to allow slower fill rates and increased accuracy. Automatic overrun correction keeps the batch size accurate over time and with system wear. With expansion module relays, up to eight-stage batching is possible; each additional stage-batching relay has an individually programmable pre-close amount. Like all meters, the PD6210 batch controller includes UL/C-UL listing and CE marking, a NEMA 4X front, and AC or DC power options.

Precision Digital PD6210 ProVu Analog Input Batch Controller

- 0-20 mA, 4-20 mA, 0-5 V, 1-5 V, ±10 V Inputs

- Start/Pause/Stop, Change Batch with Front Buttons

- Display Batch Total, Rate, Grand Total, Count or Preset

- Single or Multi-Stage Batch Control (Up to 8 Relays)

- Automatic Overrun Correction

- Flow Rate in Units per Second, Minute, Hour, or Day

- Automatic or Manual Batch Control

- Low or High Flow Alarms while Batching

- 9-Digit Grand Total with Overflow Feature

- Count Up or Down with Each Batch

- Optional Sunlight Visible Display skus for Outdoor Applications

- Onboard USB and MeterView® Pro Programming Software

General

Display: Upper display: 0.60″ (15 mm) high. Lower display: 0.46″ (12 mm) high. Both are 6 digits (-99999 to 999999), red LEDs. Both are 6 digits (-99999 to 999999), red LEDs, with lead zero blanking.

Default Display Assignment: The upper display shows batch total. The lower display shows rate with alternating units, and can be switched to show grand total, batch count, or preset with the STOP key.

Custom Display Assignment: The upper and lower displays may be assigned to rate, total, grand total, batch count, preset, set points, units (lower display only), alternating R & T, R & GT, preset & rate, max & min, or a Modbus display register. Any rate/total/grand total display may be programmed to alternate with a custom unit or tag.

Alternating Display: Displays alternate every 10 seconds when display is selected or the batch is paused.

Display Intensity: Eight user-selectable intensity levels

Display Update Rate: 5/second (200 ms)

Overrange: Display flashes 999999

Underrange: Display flashes -99999

Front Panel: NEMA 4X, IP65

Operating Methods: Three programmable front panel buttons (default START, BATCH, STOP), digital inputs, PC and MeterView Pro software, and Modbus registers.

Programming Methods: Four front panel buttons, digital inputs, PC and MeterView Pro software, Modbus registers.

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels: Logic High: 3 to 5 VDC Logic Low: 0 to 1.25 VDC

Noise Filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of calibrated span.

Recalibration: Recommended at least every 12 months.

Max/Min Display: Max (Peak) / min (Valley) readings reached by the process are stored until reset by the user or until power is cycled.

Password: Three programmable passwords restrict modification of programmed settings and two prevent resetting the totals.

Non-Volatile Memory: All programmed settings are stored in non-volatile memory for a minimum of ten years if power is lost.

Power Options: 85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max or 12-24 VDC ± 10%, 15 W max. Powered over USB for configuration only.

Fuse: Required external fuse: UL Recognized, 5 A max, slow blow; up to 6 batch controllers may share one 5 A fuse.

Isolated Transmitter Power Supply: Terminals P+ & P-: 24 VDC ± 10%. 12-24 VDC powered skus selectable for 24, 10, or 5 VDC supply (internal P+/P- switch). 85-265 VAC skus rated @ 200 mA max, 12-24 VDC powered skus rated @ 100 mA max, @ 50 mA max for 5 or 10 VDC supply.

Normal Rejection Mode: Greater than 60 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output or output-to-P+ supply.

Overvoltage Category: Installation Overvoltage Category II: Local level with smaller transient overvoltages than Installation Overvoltage Category III.

Environmental:

Operating temperature range: -40 to 65°C

Storage temperature range: -40 to 85°C

Relative humidity: 0 to 90% non-condensing

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Enclosure: 1/8 DIN, high impact plastic, UL 94V-0, color: black

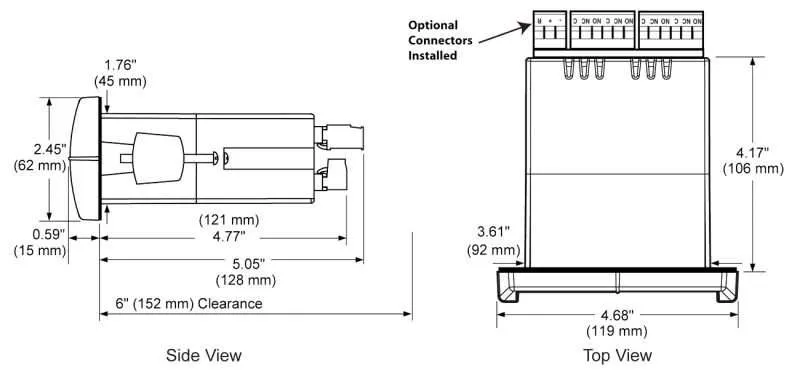

Mounting: 1/8 DIN panel cutout required: 3.622″ x 1.772″ (92 mm x 45 mm).

Weight: 9.5 oz. (269 g)

Dimensions: 4.68″ x 2.45″ x 5.64″ (119 mm x 62 mm x 143 mm) (W x H x D)

UL File Number: UL & c-UL Listed. E160849; 508 Industrial Control Equipment.

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant

Connector Type: Micro-B receptacle

Cable: USB A Male to Micro-B Cable

Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit,

Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit

Power: USB Port

PD6210 Analog Input

Inputs: Field selectable: 0-20, 4-20 mA, ±10 VDC (0-5, 1-5, 0-10 V),

Modbus PV (Slave)

Accuracy: ±0.03% of calibrated span ±1 count, square root &

programmable exponent accuracy range: 10-100% of calibrated span

Temperature Drift: 0.005% of calibrated span/°C max from 0 to 65°C

ambient, 0.01% of calibrated span/°C max from -40 to 0°C ambient

Signal Input Conditioning: Linear, square root, programmable exponent,

or round horizontal tank volume calculation.

Multi-Point Linearization: 2 to 32 points

Programmable Exponent: 1.0001 to 2.9999

Low-Flow Cutoff: 0-999999 (0 disables cutoff function)

Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd,

ddd.ddd, dddd.dd, ddddd.d, or dddddd.

Calibration Range:

| Input Range | Minimum Span Input 1 & 2 |

| 4-20 mA | 0.15 mA |

| ±10 V | 0.10 V |

An error message will appear if input 1 and input 2 signals are too close together.

Input Impedance: Voltage ranges: greater than 1 MΩ.

Current ranges: 50 – 100 Ω (depending on resettable fuse impedance).

Input Overload: Current input protected by resettable fuse, 30 VDC max.

Fuse resets automatically after fault is removed.

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

PD6310 Pulse Input

Inputs: Field selectable: Pulse or square wave 0-5 V, 0-12 V, or 0-24 V @ 30 kHz; TTL; open collector 4.7 k Ω pull-up to 5 V @ 30 kHz; NPN or PNP transistor, switch contact 4.7 k Ω pull-up to 5 V @ 40 Hz; coil (sine wave) 40 mVp-p min @ 10 kHz; Modbus PV (Slave)

Low Voltage Mag Pickup (Isolated): Sensitivity: 40 mVp-p to 8 Vp-p

Minimum Input Frequency: 0.001 Hz – Minimum frequency is dependent on high gate setting.

Maximum Input Frequency: 30,000 Hz (10,000 for Low Voltage Mag Pickup)

Input Impedance: Pulse input: Greater than 300 kΩ @ 1 kHz. Open collector/switch input: 4.7 k Ω pull-up to 5 V.

Accuracy: ±0.03% of calibrated span 1 count

Display Update Rate: Total: 10/sec, Rate: 10/sec to 1/1000 sec

Temperature Drift: Rate display is not affected by changes in temperature.

Multi-Point Linearization: 2 to 32 points

Low-Flow Cutoff: 0-999999 (0 disables cutoff function)

Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd.

Calibration: May be calibrated using K-factor, scale using internal calibration, or calibrate by applying an external calibration signal.

K-Factor: Field programmable K-factor converts input pulses to rate in engineering units. May be programmed from 0.00001 to 999,999 pulses/unit.

Calibration Range: Input 1 signal may be set anywhere in the range of the controller; input 2 signal may be set anywhere above setting.

Filter: Programmable contact de-bounce filter, 40 to 999 Hz maximum input frequency allowed with low speed filter.

Time Base: Second, minute, hour, or day

Low Gate: 0.1-99.9 seconds; this function determines how often the incoming pulses are calculated and the rate display is updated.

High Gate: 2.0-999.9 seconds; this function determines how long to wait for pulses before the display goes to zero. This function is used to display slow pulse rates.

Note: The combination of the low and high gate functions makes it possible to have a fast display update for fast pulse rates while displaying slow pulse rates, if needed. For example: If the low gate is set to 1.0 second and the high gate to 999.9 second, with a fast pulse rate the display is updated every second; with a slow pulse rate the controller is capable of waiting up to 999.9 seconds before calculating the rate, making it possible to display a very slow rate down to 1 pulse/999.9 second (0.001 pulse/second).

Batch Controller

Rate Display Indication: 0 to 999999, lead zero blanking. “R” LED illuminates while displaying rate.

Total Displays & Grand Total Overflow: 0 to 999,999; automatic lead zero blanking. “T” LED is illuminated while displaying batch total and “GT” for grand total. Up to 999,999,999 with total-overflow feature. “![]() ” is displayed to the left of grand total overflow and

” is displayed to the left of grand total overflow and ![]() LED is illuminated.

LED is illuminated.

Batch Total Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd. Note: Total decimal point is independent of rate decimal point.

Totalizer: Calculates total based on rate and field programmable multiplier to display total in engineering units. Time base must be selected according to the time units in which the rate is displayed.

Total Conversion Factor: 0.00001 to 999,999

Batch Preset: 0.00001 to 999,999 based on batch total decimal point.

Automatic Batch Restart Delay: 00000.1 to 999.9 seconds. The batch will automatically restart after completion of the last batch.

Grand Total Rollover: Totalizer rolls over when display exceeds 999,999,999. Relay status reflects the display value.

Grand Total Alarms: Up to seven, user selectable under Setup menu. Any set point can be assigned to grand total and may be programmed anywhere in the range of the controller for grand total alarm indication.

Note that Relay 1 should always be assigned to batch control (total).

Grand Total Reset: Via front panel button, external contact closure on digital inputs, automatically via user selectable preset value and time delay, or through serial communications.

Grand Total Reset Password: A grand total password may be entered to prevent resetting the grand total from the front panel.

Non-Resettable Grand Total: The grand total can be programmed as a non-resettable total by entering the password “050873”.

Caution: Once the Grand Total has been programmed as “non-resettable” the feature cannot be disabled.

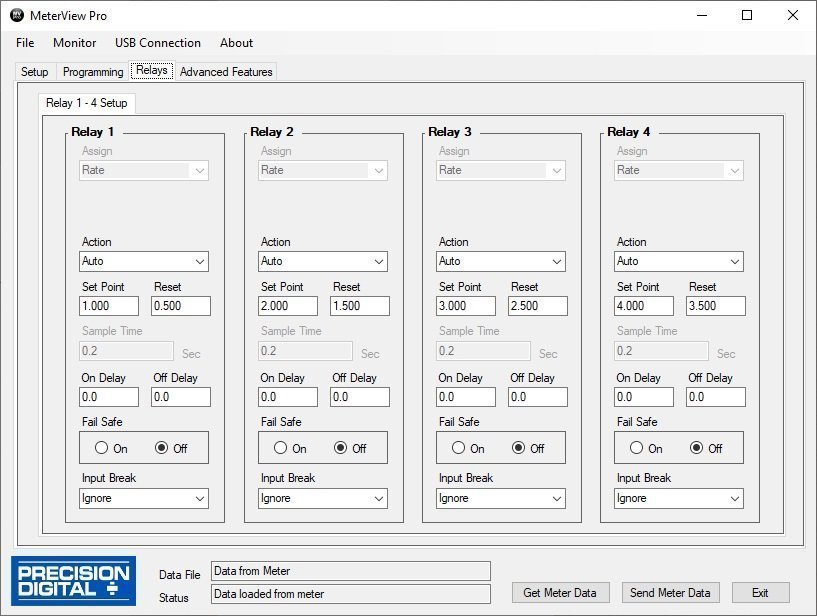

Relays

Rating: 2 or 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 W) @ 125/250 VAC for inductive loads

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Relay Assignment: Relays may be assigned to batch control, sampling, rate, or grand total alarms.

Preclose: 0-100% of batch size, individually user programmable for each additional batch control relay beyond the first.

Alarm Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

Batching Relay Operation: Single or (2 to 8) multi-relay batching with optional preclose for multi-stage operation. Each additional relay may be programmed with an individual preclose value.

Alarm Relay Operation: Automatic (non-latching), latching (requires manual acknowledge), sampling (based on rate or grand total), pump alternation control (2 to 8 relays), off (disable unused relays), and manual on/off control mode. Alarms are active only when the batch is running.

Alarm Relay Reset: User selectable via front buttons, digital inputs, or PC

1. Automatic reset only (non-latching), when input passes the reset point or total is reset to zero.

2. Manual reset only, when batch is stopped (latching).

3. Manual reset only after alarm condition has cleared (latching)

Note: Front panel button or digital input may be assigned to acknowledge relays programmed for manual reset. This replaces one of the standard batch control function keys. Only the PAUSE/STOP key function is possible during a batch process, so manual reset may only be done when thecontroller is in STOP mode.

Deadband: 0-100% of span, user programmable

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay.

Note: Relay coil is energized in non-alarm condition. In case of power failure, relay will go to alarm state.

Auto Initialization: When power is applied, relays will reflect the state of the input. Alarms are active only when the batch is running.

Isolated 4-20 mA Transmitter Output

Output Source: Rate/process, total, grand total, max, min, set points 1-8, manual control setting, or Modbus input

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated: 4.000 to 20.000 = 4-20 mA output

Analog Output Programming: 23.000 mA maximum for all parameters: Overrange, underrange, max, min, and break

Accuracy: ±0.1% FS ±0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µA/°C max from -40 to 0°C ambient Note: Analog output drift is separate from input drift.

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All skus rated @ 40 mA max.

External Loop Power Supply: 35 VDC maximum

Output Loop Resistance:

| Power supply | Minimum | Maximum |

| 24 VDC | 10 Ω | 700 Ω |

| 35 VDC (external) | 100 Ω | 1200Ω |

Serial Communications

Protocol: Modbus® RTU

Controller Address/Slave ID: 1 – 247

Baud Rate: 300 – 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms or transmitter always on for RS-422 communication

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 – 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Note: Refer to the PD6000/PD7000 Modbus Register Tables located in the documentation section of this page.

Digital I/O Expansion Module

Channels: 4 digital inputs & 4 digital outputs per module

System: Up to 2 modules for a total of 8 inputs & 8 outputs

Digital Input Logic: High: 3 to 5 VDC Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC Low: 0 to 0.4 VDC

Source Current: 10 mA maximum

Sink Current: 1.5 mA minimum

+5 V Terminal: To be used as pull-up for digital inputs only.

4-Relay Expansion Module

Relays: Four Form A (SPST) rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (. 50 watts) @ 125/250 VAC for inductive loads.

Applications

Batch Control

A ProVu batch controller can be programmed for a wide variety of applications. Setup is easy for single or multi-stage batching. Automatic overrun correction keeps the batch size accurate, even over time and with system wear. It can record grand total, or nonresettable grand total with a time base of seconds, minutes, hours or days. The user can program a conversion factor, and configure a non-resettable grand total, and password protection.

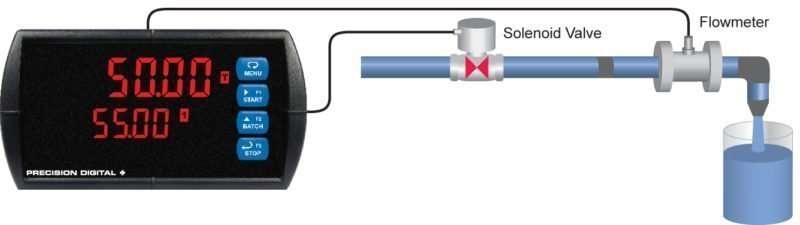

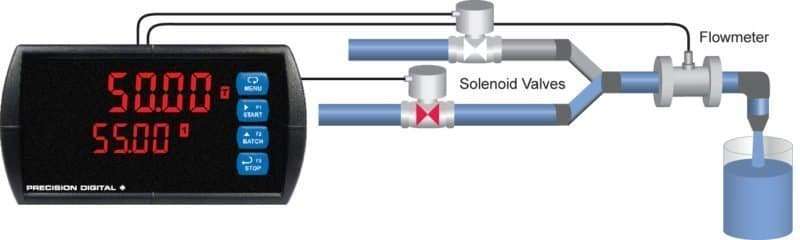

Single and Multi-Stage Batching

The ProVu can be used as a single or multi-stage batch controller. Relays assigned to the total act as batch control relays, with additional relays beyond the first including a preclose value. The preclose deactivates the relay before the batch is finished, to allow slower fill rates and a more accurate batch finish. With expansion module relays, up to eight-stage batching is possible. Each additional stage batching relay has an individually programmable preclose amount.

Single Stage Batch Control

Multi-Stage Batch Control

Manual Multi-Stage Batch Control Operation

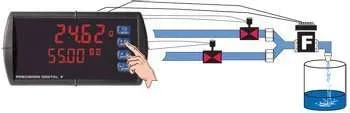

1. System Setup

Both valves are closed with an empty barrel in place. The batched total is displayed in the upper display, the preset is selected for the lower display. 2. Batch Start

2. Batch Start

The START button is pressed, with both valves open. The barrel begins to fill. 3. Preclose Valve

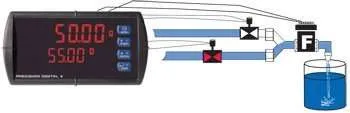

3. Preclose Valve

When the batch total reaches a value of 50.00 (Preset [55.00] Preclose [5.00]) the full-flow valve closes. The fill rate of the tank slows as a result. 4. Completed Batch

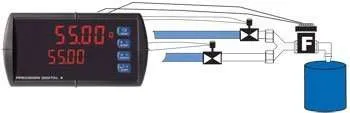

4. Completed Batch

When the batch total equals the preset amount, the restricted-flow valve closes. The barrel is now full. If some overrun occurs, the next batch will adjust for this offset amount to maintain accuracy. 5. Change Preset

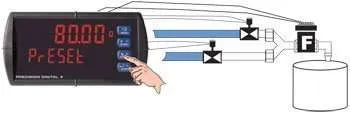

5. Change Preset

After placing a new, empty barrel, a new preset fill amount may be selected with the Batch key, while the process is stopped. 6. Begin New Batch

6. Begin New Batch

Press the START key and a new batch will begin. With both valves open, the process continues. 7. Pause/Stop

7. Pause/Stop

At any time, the STOP button may be pressed, once to Pause the process, or twice to cancel the batch, which stops the process.

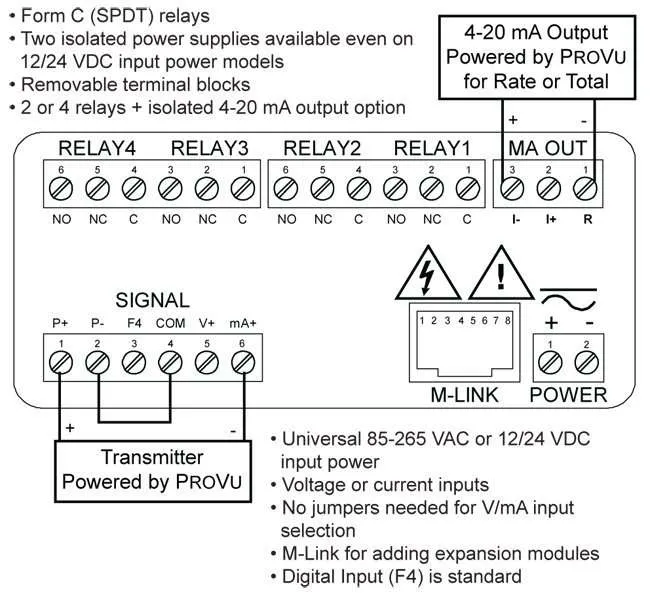

Connections

PD6210 Connections

PD6310 Connections

Mounting Dimensions

Notes:

- Panel cutout required: 1.772″ x 3.622″ (45mm x 92mm)

- Panel thickness: 0.040 – 0.250″ (1.0mm – 6.4mm)

- Mounting brackets lock in place for easy mounting

- Clearance: Allow 6″ (152 mm) behind the panel

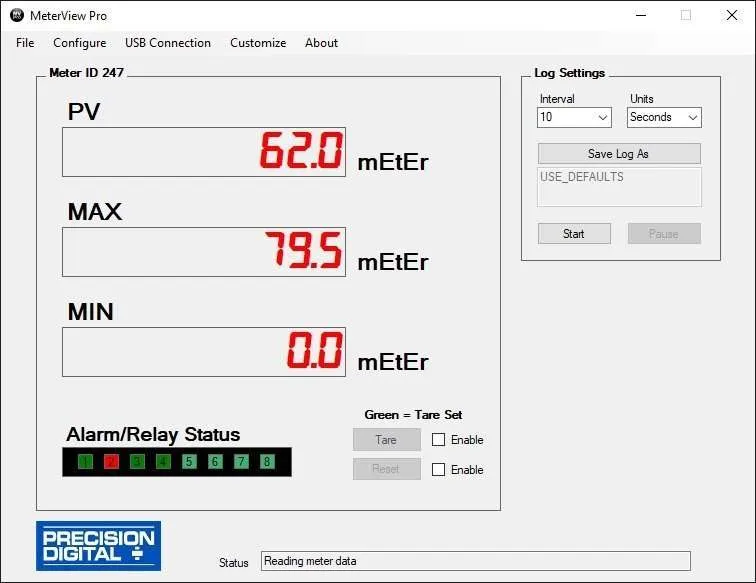

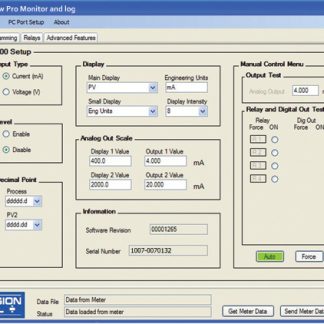

MeterView® Pro Software

This software is accessible via the onboard USB connection on all Helios large display meters, ProVu panel meters, and ProVu-based ProtEX-MAX explosion-proof meters produced since 6 September 2016 (firmware version 4.0 or higher). In order for meters produced prior to 6 September 2016 (firmware version 3.1 or lower) to establish digital communications with a PC, a serial communications adapter is required. For an RS-232 connection, use a PDA1232 adapter.

To determine the software version of a meter:

- Go to the Diagnostics menu (

) and press Enter button.

) and press Enter button. - Press Up arrow button and scroll to Information menu (Info

).

). - Press Enter to access the software number (

), version (

), version ( ), and serial number (

), and serial number ( ) information. Write down the information as it is displayed. Continue pressing Enter until all the information is displayed.

) information. Write down the information as it is displayed. Continue pressing Enter until all the information is displayed. - The meter returns to Run Mode after displaying all the settings.

Monitor and Datalog

Setup

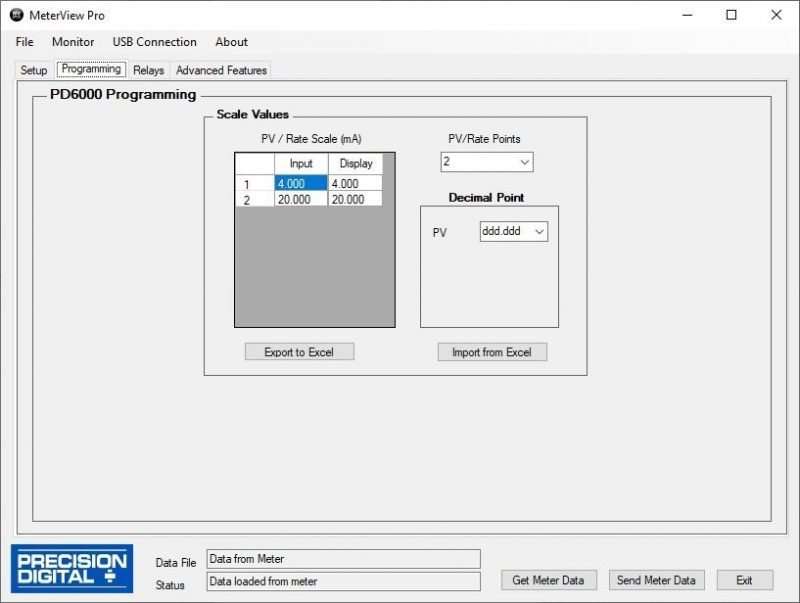

Programming

Relays

Data Sheet: LDS6210 Datasheets

Instruction Manual: LIM6210 Instruction Manuals