Input

15, 30, 150, 300 mV Unipolar Input Ranges;

±15, ±25, ±150, ±250 mV Bipolar Input Ranges

Helios Features

- Large 1.80″ Digits

- Dual Line Display

- Six Full Digits on Each Line

- Readable From 100 Feet Away

- Superluminous Sunlight Readable Display

- NEMA 4X, IP65 Rated Field Mountable Enclosure

- Great for Outdoor Use: -40 to 150°F (-40 to 65°C)

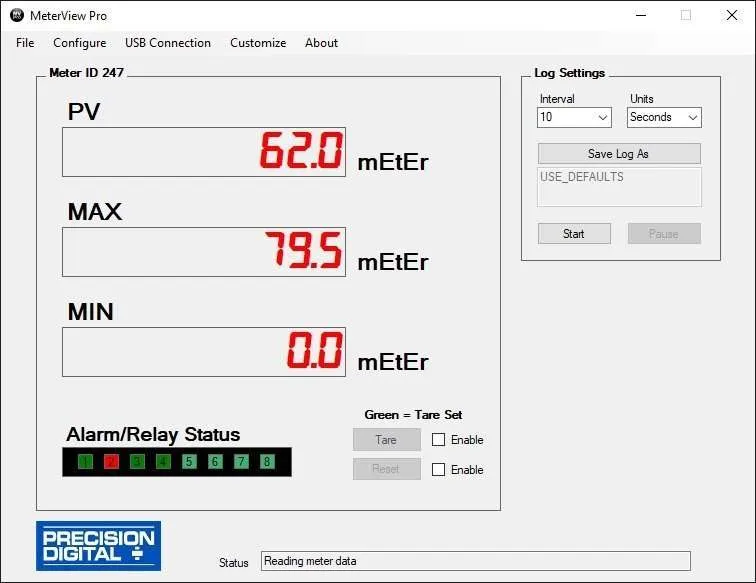

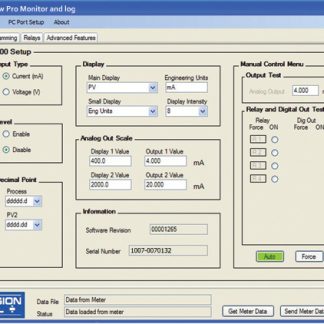

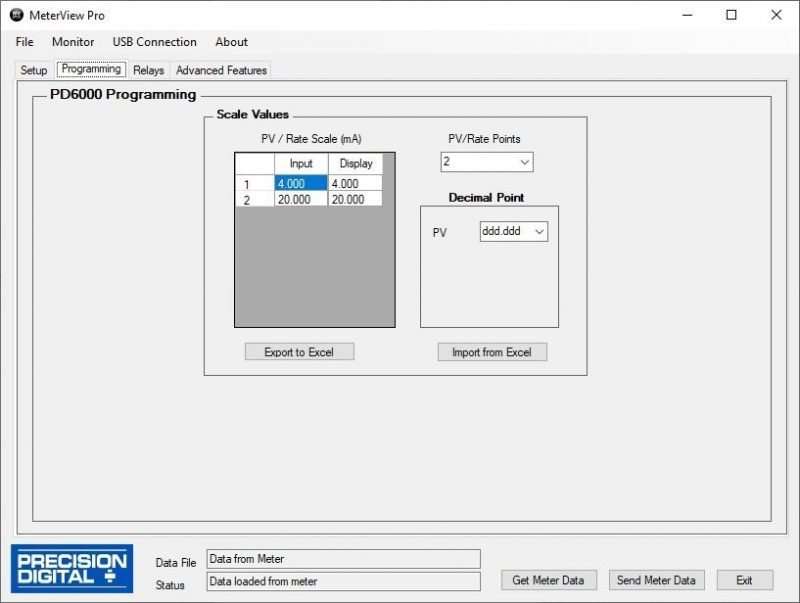

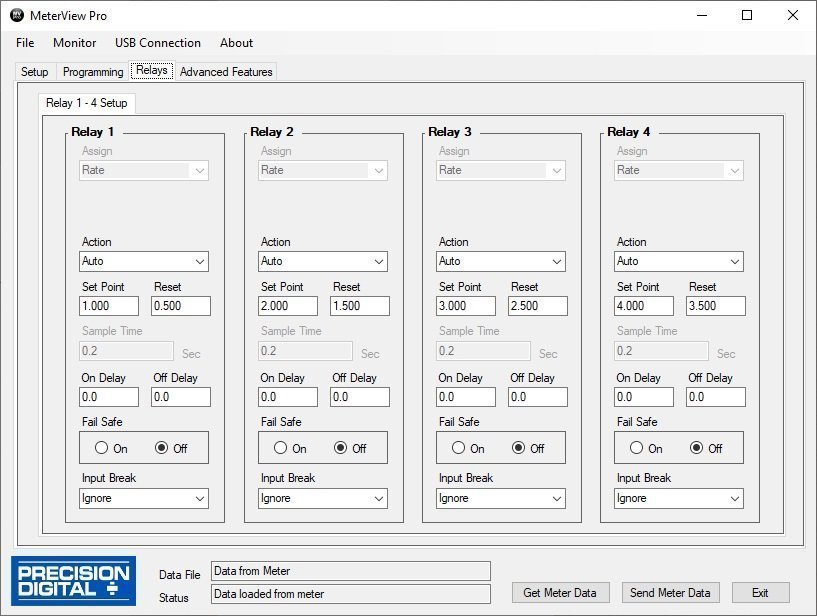

- Program the Meter from a PC with Onboard USB and MeterView® Pro

PD2-6100 Features

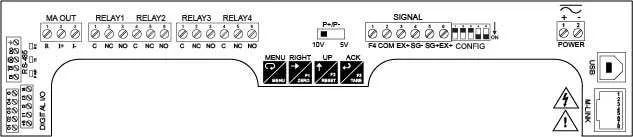

- Selectable 5 or 10 VDC Sensor Excitation

- Supports up to Twelve (12) 350 Ω Load Cells

(Minimum Load Resistance of 28 Ω) - Capture or Programmable Tare Feature

- Auto-Zero Feature Eliminates Zero Drift

- Ratiometric Operation

- Max/Min or Peak/Valley Hold Feature

- Display One Input in Two Different Scales (e.g. Weight & Volume)

- Rounding Function 1, 2, 5, 10, 20, 50, or 100

What sets the Helios apart from other Large Display Meters is its dual line display with super bright LEDs that can be read even in bright sunlight and up to 100 feet away. Based on Precision Digital’s popular line of ProVu® digital panel meters, the Helios can satisfy a wide variety of level, flow, temperature, pressure, & weight applications. It is available with models that accept 4-20 mA, thermocouple, RTD, pulse, strain gauge, AC and DC volts and current, and even Modbus®.

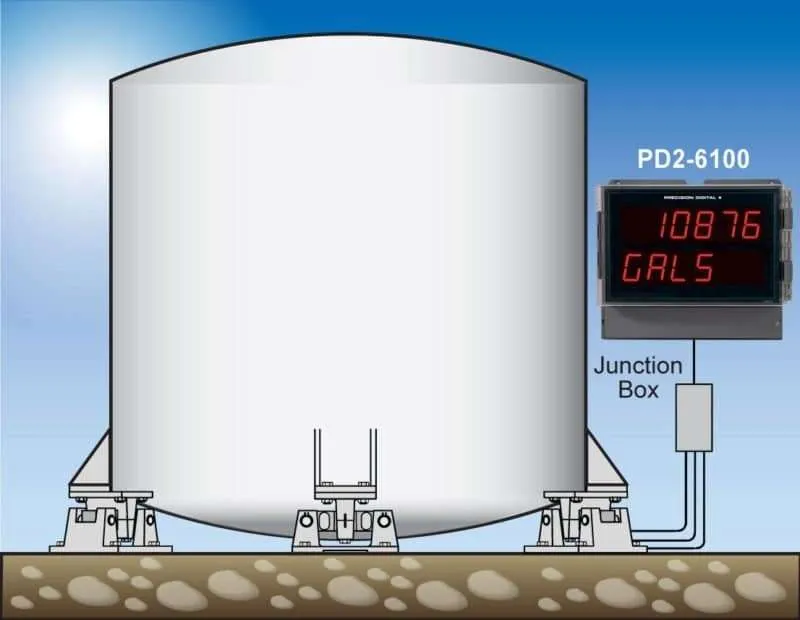

Go with the Helios PD2-6100 when you have a weighing application where you need to read the display from a distance, or outside in the bright sunlight in temperatures between -40 to 150°F. The PD2-6100 tare feature can be used to remove the weight of the container from the weight calculation. You can even re-transmit the weight signal with the PD2-6100’s optional 4-20 mA output.

General

Display: Two lines with 1.8″ (46 mm) high digits, red LEDs; 6 digits per line (-99999 to 999999), with lead zero blanking

Display Intensity: Eight intensity levels

Display Update Rate: 5/second (200 ms)

Overrange: Display flashes 999999

Underrange: Display flashes -99999

Display Assignment: The upper and lower displays may be assigned to PV1, PV2, PCT (percent), max/min, alternate max & min, set points, units (lower display only), or Modbus input.

Programming Methods: Four SafeTouch through-glass buttons when cover is installed. Four internal pushbuttons when cover is removed.

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels: Logic High: 3 to 5 VDC; Logic Low: 0 to 1.25 VDC

Noise filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of calibrated span

Recalibration: Calibrated at the factory. Recalibration is recommended at least every 12 months.

Max/Min Display: Max / min readings reached by the process are stored until reset by the user or until power to the meter is turned off.

Password: Three programmable passwords restrict modification of programmed settings.

Non-Volatile Memory: All programmed settings are stored in nonvolatile memory for a minimum of ten years if power is lost.

Power Options: 85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max or 12-24 VDC ± 10%, 15 W max. Powered over USB for configuration only.

Fuse: Required external fuse: UL Recognized, 5 A max, slow blow; up to 6 meters may share one 5 A fuse.

Isolated Sensor Power Supply: Terminals Ex+ & Ex-: 10 VDC or 5 VDC ± 10%. Rated @ 350 mA max. Note: Do not use 24 VDC to power strain gauge bridge

Normal Mode Rejection: Greater than 60 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output or output-to-P+ supply.

Overvoltage Category: Installation Overvoltage Category II: Local level with smaller transient overvoltages than Installation Overvoltage Category III.

Environmental:

T6 Class operating temperature range Ta = -40 to 60°C

T5 Class operating temperature range Ta = -40 to 65°C

Max Power Dissipation: PD8 Series: Maximum power dissipation limited to 15.1 W. See PD8 instruction manual for additional details.

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Enclosure: UL Type 4X, IP65 rated. Polycarbonate & glass blended plastic case, color: gray. Includes four PG11 through-hole conduit openings, with two factory installed PG11, IP68, black nylon threaded hole plugs with backing nuts.

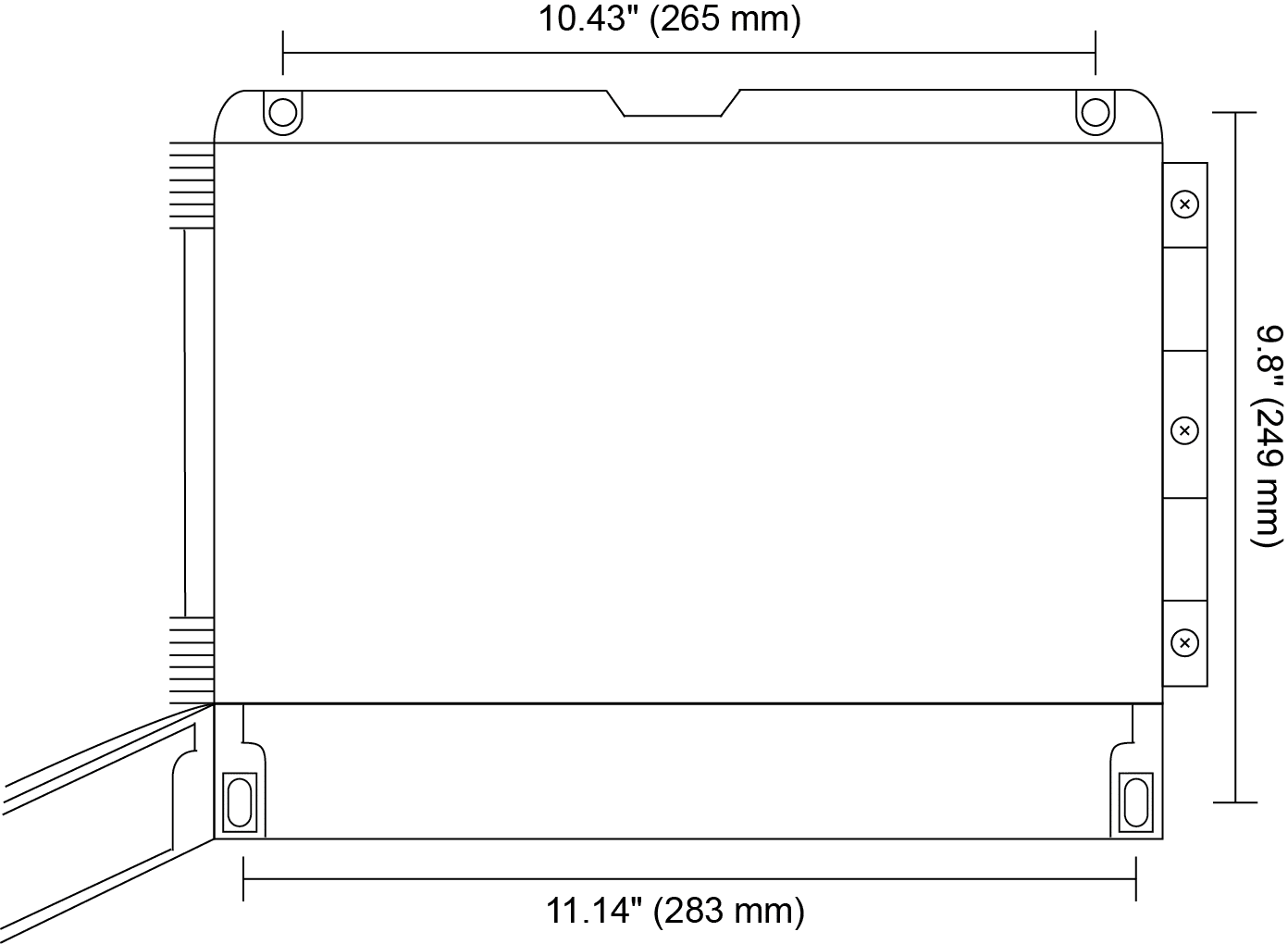

Wall Mounting: Four (4) mounting holes provided for screwing the meter into wall.

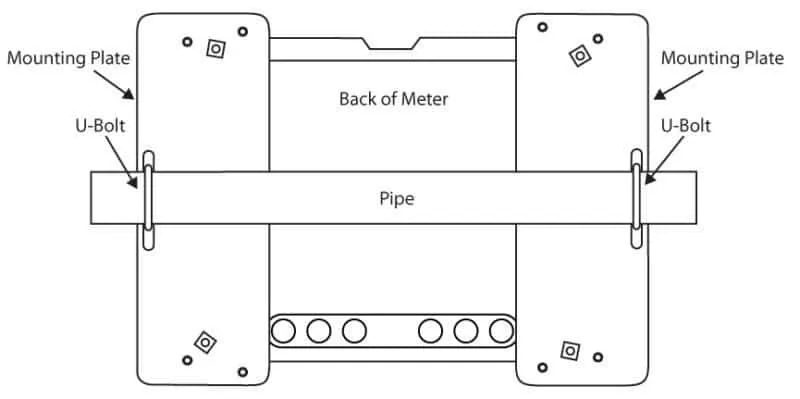

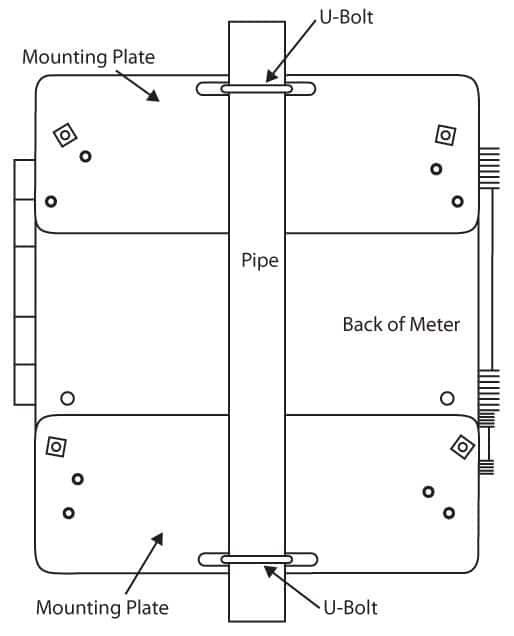

Pipe Mounting: Optional pipe mounting kit (PDA6260) allows for pipe mounting. Sold separately.

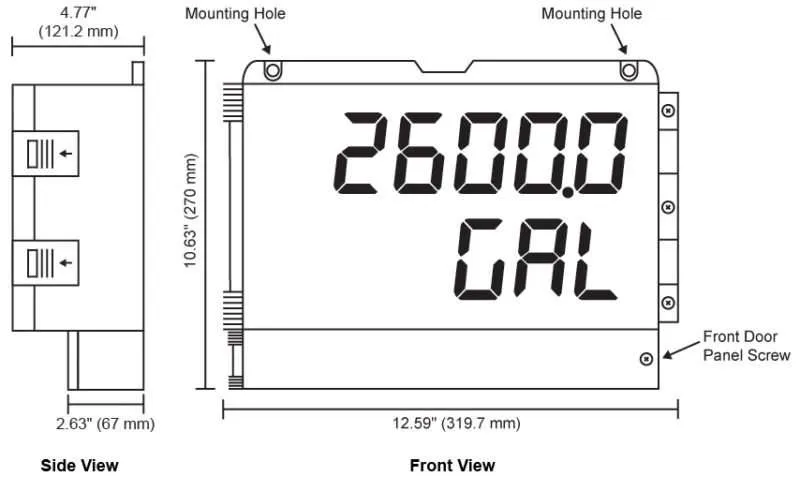

See PD2-6100 manual for instructions.Dimensions: 10.63″ x 12.59″ x 4.77″ (270 mm x 319.7 mm x 121.2 mm) (H x W x D)

Weight: 6.10 lbs (2.76 kg)

UL File Number: UL & C-UL Listed. E160849; 508 Industrial Control Equipment.

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant Connector Type: Micro-B receptacle Cable: USB A Male to Micro-B Cable Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit, Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit Power: USB Port

Strain Gauge Input

Inputs: Field selectable: 0-15, 0-30, 0-150, 0-300 mV, ±15, ±25, ±150, ±250 mV, or Modbus PV (Slave)

Accuracy: ±0.03% of calibrated span ±1 count

Minimum Load Resistance: 28 Ω @ 5 V or 10 V

Maximum Excitation Current: 350 mA @ 5 V or 10 V

Temperature Drift: 0.002% of calibrated span/°C max from 0 to 65°C ambient, 0.005% of calibrated span/°C max from -30 to 0°C ambient

Function: Linear with multi-point linearization

Low-Flow Cutoff: 0-999999 (0 disables cutoff function)

Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd.

Calibration Range:

| Input Range | Minimum Span Input 1 & Input 2 |

| 15 mV | 0.2 mV |

| 25 mV, 30 mV | 0.4 mV |

| 150 mV | 2.0 mV |

| 250 mV, 300 mV | 4.0 mV |

An Error message will appear if the input 1 and input 2 signals are too close together.

Input Impedance: Voltage ranges: greater than 1 MΩ.

Relays

Rating: 2 or 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 watts) @ 125/250 VAC for inductive loads such as contactors, solenoids, etc.

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

Relay Operation: Automatic (non-latching), latching (requires manual acknowledge), sampling (based on time), pump alternation control (2 to 8 relays), Off (disable unused relays and enable interlock feature, manual on/off control mode).

Relay Reset: User selectable via front panel buttons or digital inputs.

1. Automatic reset only (non-latching), when input passes the reset point.

2. Automatic + manual reset at any time (non-latching).

3. Manual reset only, at any time (latching).

4. Manual reset only after alarm condition has cleared (latching).

Note: Front panel button or digital input may be assigned to acknowledge relays programmed for manual reset.

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay.

Auto Initialization: When power is applied to the meter, relays will reflect the state of the input to the meter.

Serial Communications

Compatability: EIA-485

Connectors: Removable screw terminal connector

Max Distance: 3,937′ (1,200 m) max

Status Indication: Separate LEDs for Power (P), Transmit (TX), and Receive (RX)

Protocol: Modbus® RTU (Slave Only)

Meter Address/Slave ID: 1 – 247

Baud Rate: 300 – 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms or transmitter always on for RS-422 communication

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 – 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Note: Refer to the ProVu Modbus Register Tables for details

Isolated 4-20 mA Transmitter Output

Output Source: Process variable (PV), max, min, set points 1-8, manual control setting, or Modbus input

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated: 4.000 to 20.000 = 4-20 mA output

Analog Output Programming: 23.000 mA maximum for all parameters:

Overrange, underrange, max, min, and break

Accuracy: ± 0.1% of span ± 0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µA/°C max from -40 to 0°C ambient

Note: Analog output drift is separate from input drift.

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All skus rated @ 40 mA max.

| Power supply | Minimum | Maximum |

| 24 VDC | 10Ω | 700Ω |

| 35 VDC (external) | 100Ω | 1200Ω |

Digital Inputs and Outputs

Channels: 4 digital inputs & 4 digital outputs per module

System: One expansion module may be added for a total of 8 inputs & 8 outputs

Note: The jumper located between the RJ45 connectors must be removed on the expansion module.

Digital Input Logic: High: 3 to 5 VDC; Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC; Low: 0 to 0.4 VD

Source Current: 10 mA maximum output current

Sink Current: 1.5 mA minimum input current

+5 V Terminal: To be used as pull-up for digital inputs only. Connect normally open pushbuttons across +5 V & DI 1-4. Warning: DO NOT use +5 V terminal (pin 1) to power external devices.

Function Assignment: The on-board digital inputs (1-4) are designed to mimic the behavior of the front panel buttons (Menu, F1, F2, & F3). If you wish to change their behavior, re-assign F1-F3 to the desired function, then change the corresponding digital input to match.

4-Relay Expansion Module

Relays: Four Form A (SPST) rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (approx. 50 watts) @ 125/250 VAC for inductive loads.

Meter Mounting Holes

Meter Mounting Holes