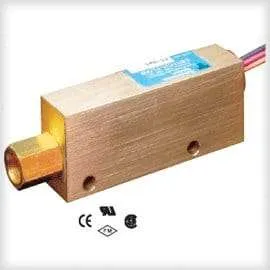

The Meister DWG Flow Monitor & Indicator is a precision flow measurement device designed to provide reliable and accurate monitoring of liquid flow in a variety of industrial applications. Utilizing the float measuring principle, this flow monitor is ideal for use in cooling systems, mechanical and medical engineering, pharmaceutical and chemical industries, as well as research and development environments. With high reliability and switch accuracy, the DWG Flow Monitor ensures consistent performance even in demanding conditions.

Product Features:

- High Reliability: Built to deliver consistent and accurate flow monitoring across a range of industrial applications.

- Wide Measuring Range: Available in multiple models to accommodate flow rates from 0.1 to 50 l/min, making it versatile for different needs.

- Universal Orientation: The DWG can be installed in any orientation, providing flexibility and ease of integration into existing systems.

- Adjustable Switch Point: The switch point is infinitely adjustable by the operator, allowing for precise control and customization based on specific flow requirements.

- Durable Construction: Available in both brass and stainless steel versions, with high-quality DURAN® 50 sight glass and robust wetted parts for long-term durability.

- ATEX and UL Compliance: An EX-version compliant with the ATEX directive is available for use in potentially explosive environments, and UL Recognized versions are also available for enhanced safety.

- Ingress Protection: Rated IP65 and IP67, providing strong protection against dust and water ingress, ensuring reliable operation in harsh conditions.

High-Traffic Keywords:

- Flow Monitor

- Flow Indicator

- Industrial Flow Measurement

- Cooling System Flow Monitor

- ATEX Flow Monitor

- UL Recognized Flow Monitor

- Pharmaceutical Flow Monitoring

- Chemical Industry Flow Control

The Meister DWG Flow Monitor & Indicator is an essential tool for professionals who require precise and dependable flow measurement in industrial environments. Its robust design, flexibility, and compliance with international safety standards make it a trusted solution for ensuring accurate monitoring and control of flow rates in critical applications.