Introducing the Dwyer Series IEF Insertion Electromagnetic Flow Meter, a cutting-edge solution for accurate and reliable fluid velocity measurement. This state-of-the-art flow meter utilizes advanced electromagnetic technology to ensure precise readings in various applications. With its user-friendly design, installation and operation are a breeze, making it a versatile choice for pipe sizes ranging from 4 to 36″ (101.6 to 914.4 mm).

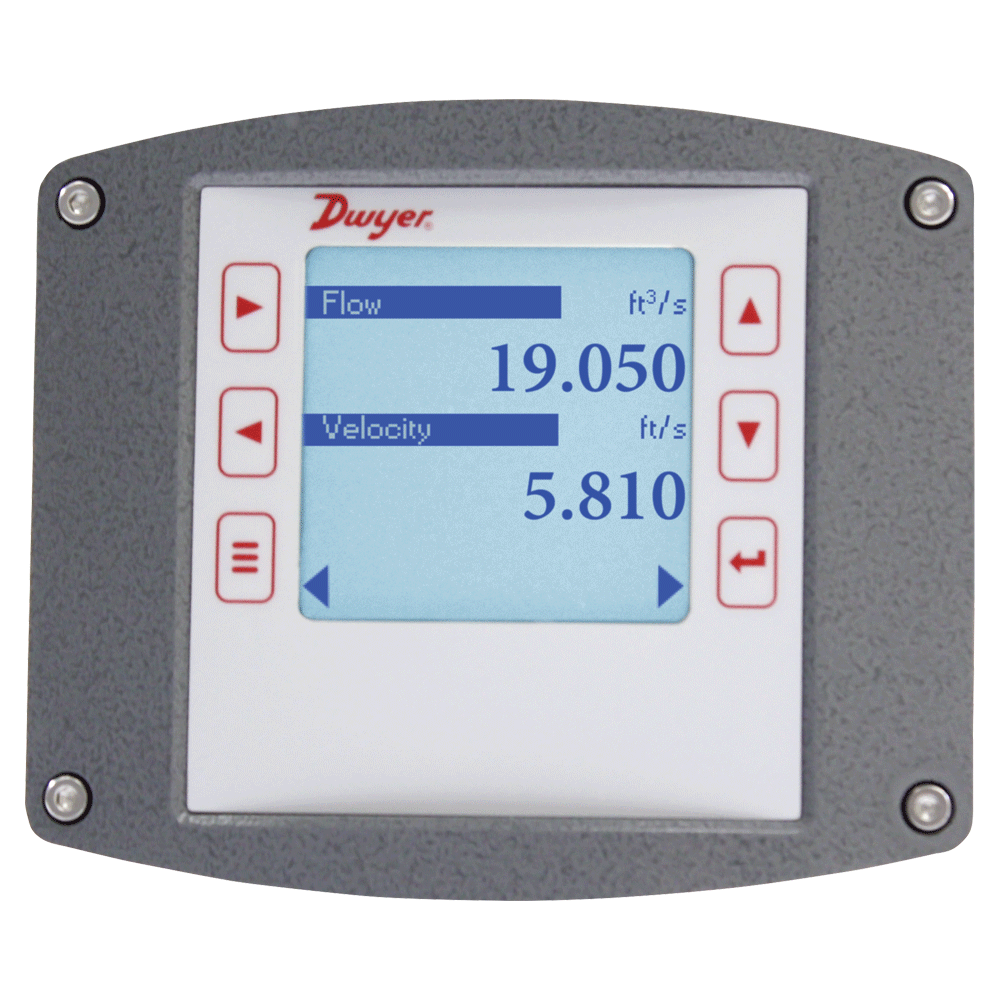

Equipped with a wide range of output options, the Dwyer Series IEF offers unparalleled flexibility. Choose from selectable BACnet MS/TP or Modbus® RTU communications protocol over 2-wire RS-485, in addition to the standard analog, frequency, and alarm outputs. This allows seamless integration with your existing systems, providing real-time data and enhancing overall operational efficiency.

The Dwyer Series IEF Insertion Electromagnetic Flow Meter finds its application in a multitude of industries. Whether it’s boiler feedwater, chilled water, condenser water in open and closed-loop systems, irrigation, municipal water distribution, process and coolant flow, groundwater remediation, chemical processing, pump protection, wastewater management, or mining operations, this flow meter delivers unparalleled accuracy and reliability.

Experience the precision and performance of the Dwyer Series IEF Insertion Electromagnetic Flow Meter, a game-changer in fluid velocity measurement. Trust in Dwyer’s commitment to excellence and unlock the potential of your applications with this state-of-the-art solution.

Service : Compatible clean or dirty non coating, conductive liquids.

Range : 0 to 20 ft/s (0 to 6 m/s).

Wetted Materials : Body shaft/fitting: 316SS; Electrodes: 316SS; Electrode cap: Polymer/Polystyrene; O-ring: Silicon.

Accuracy : High accuracy units: ±0.5% of reading at calibrated velocity; ±1% of reading from 2 to 20 ft/s (0.6 to 6 m/s); ±0.02 ft/s (±0.006 m/s) at < 2 ft/s (0.6 m/s);

Standard accuracy units: ±1% FS.

Temperature Limits : Ambient: -20 to 160°F (-29 to 71°C); Process: 15 to 250°F (-9 to 121°C); Storage: -40 to 185°F (-40 to 85°C).

Process Connection : 1″ NPT or BSPT with accessory full port ball valve options.

Pressure Limits : 400 psi (27.6 bar) @ 100º F (37.8°C).

Pressure Drop : < 0.1 psi at 12 ft/s in 4″ (101.6 mm) and larger pipe.

Outputs : (1) Analog: 4 to 20 mA, 0 to 5 V, 0 to 10 V or 2 to 10 V (display selectable);

(1) Pulse/Frequency: 0 to 15 V peak pulse, 0 to 500 Hz or scalable pulse output (display selectable);

(2) Alarm: (1) Empty pipe detection or minimum/maximum velocity, (display selectable);

(1) Reverse flow output indication.

Power Requirements : 12 to 42.4 VDC, .25 A @ 24 VDC; 12 to 36 VAC.

Electrical Connection : Removable terminal blocks, model selectable 1/2″ female NPT conduit connection, PG 16 gland or PG 16 gland with (2) 10′ (3 m) 9 conductor 22 AWG plenum rated cables, accessory cable lengths up to 200′ (61 m) optional.

Display : 2″ ( 5.08 cm) x 2″ (5.08 cm) graphic LCD with backlight.

Conductivity : >20 microsiemens.

Enclosure Material : Powder coated die cast aluminum.

Enclosure Ratings : NEMA 6P (IP68) (Non display skus); NEMA 4X (IP66) (-LCD option).

Agency Approvals : BTL, CE, NSF/ANSI 61 and 372.

COMMUNICATIONS (-COM OPTION)

Type : BACnet MS/TP or Modbus® RTU communication protocol (default disabled, display selectable).

Supported Baud Rates : 9600, 19200, 38400, 57600, 76800, or 115200 bps (display selectable).

Device Load : 1/8 unit load.

ADDITIONAL SPECIFICATIONS

Applicable Pipe Material : Most popular plastic and metal pipes; i.e. Carbon steel, SS, copper, UPVC/PVDF, galvanized steel, mild steel, and brass*.

Applicable Pipe Size : 4 to 36″ (100 to 900 mm), model dependent. See model chart on catalog page.

Diameter Length Requirement :>10 upstream, >5 downstream.

Glycol : 0 to 100% display selectable.

*Brass fittings and pipe not for use with NSF Certified Model.