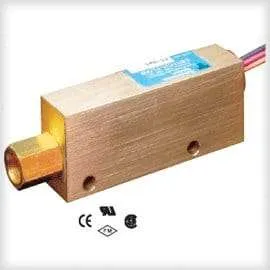

The SERIES DPW Digital Paddlewheel is an economical choice for applications where liquid flow measurement is desired. This Series offers two programmable totalizers via the optional LCD and RS-232/RS-485 interface, two optically isolated flow pulse outputs, and selectable 0 to 5 VDC or 4 to 20 mA flow outputs (optional temperature).

Product Applications

- Liquid monitoring

- Chemical proportioning or batching

- Laboratory equipment

Service : Liquids compatible with wetted materials.

Wetted Materials : DPW-XP: Polypropylene; Seals (see options in sku chart), PVDF and nickel tungsten carbide paddlewheel, acrylic lid; Bearings: PVDF sapphire. DPW-XT: PVDF; Seals (see options in sku chart), PVDF and zirconia ceramic paddlewheel, PVDF lid; Bearings: PVDF sapphire.

Accuracy : ±1% FS.

Repeatability : ±0.25% FS.

Response Time : 1 second above 10% of FS, 2 seconds below 10% of FS.

Output Signal : Linear 0 to 5 VDC (3000 Ω min. load impedance); 4 to 20 mA (500 Ω max. loop resistance) for flow and temperature option; Pulse output: 3.3 VDC, 3K min. load impedance.

Electrical Connection : 12 pin cable.

Digital Interface : RS-232; RS-485.

Temperature Limits : 14 to 140°F (-10 to 60°C).

Pressure Limit : 10 bar (150 psig).

Power Requirements : 11 to 26 VDC.

Display : 2 row, 16 character LCD with backlight (optional).

Process Connections : DPW-05: 3/8″ FNPT; DPW-10: 1/2″ FNPT; DPW-17: 3/4″ FNPT; DPW-35: 1″ FNPT.

Enclosure Rating : IP65.

Weight : 1.60 lb (0.73 kg).