The Series 629C Wet/Wet Differential Pressure Transmitter monitors the differential pressure of air and compatible gases and liquids with 0.5% accuracy. The design employs dual pressure sensors converting pressure changes into a standard 4 to 20 mA output signal or field-selectable voltage. Small internal volume and minimal moving parts result in exceptional response and reliability. The terminal block, as well as a zero adjustment button, are easily accessed under the top cover.

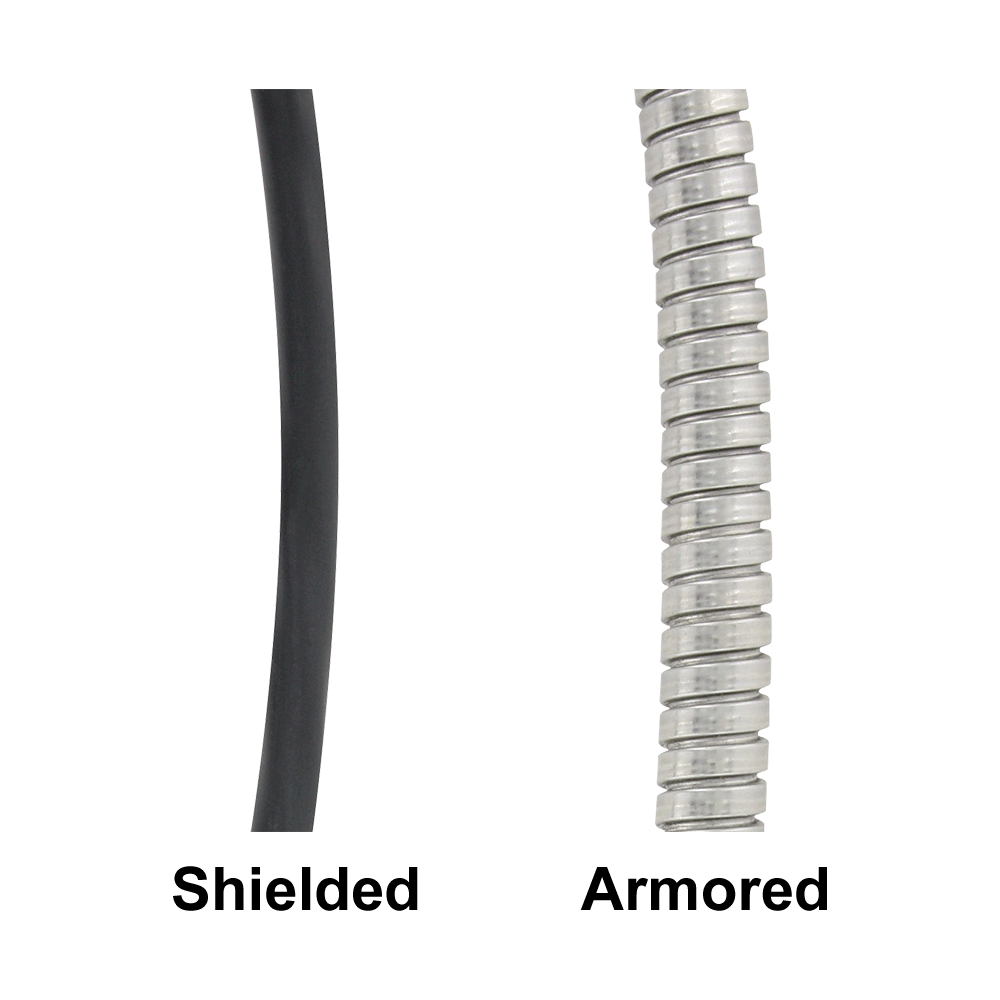

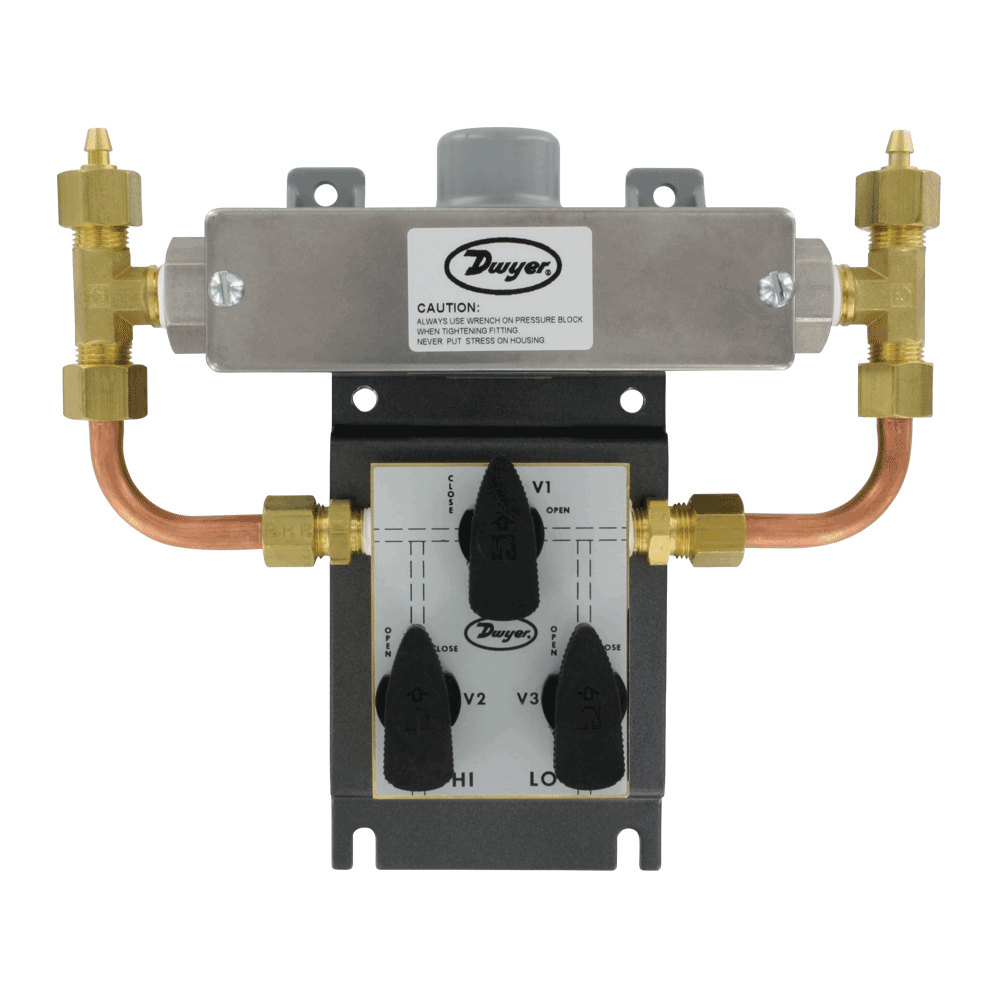

The Series 629C, with the optional factory-installed remote sensors, is connected to the unit, either via armored or shielded cable, and available in 10 and 20′ lengths. Installation is much simpler, reducing labor and material cost versus traditional copper piping installations and no need for valve manifolds.

The 629C family has a robust NEMA 4X (IP66) construction, which is also available with an integral LCD for localized data monitoring.

Product Applications

- Flow elements

- Heat exchangers

- Filters

- Coils

- Chiller

- Pumps

Service: Compatible gases and liquids.

Wetted Materials: Without valve: 316, 316L SS. Additional wetted parts with valve option: Buna-N, silicone grease, PTFE, brass 360, copper, and reinforced copolymer.

Accuracy : ±0.5% FS (includes linearity, hysteresis & repeatability)Stability:±1% FS/year.

Temperature Limits : 0 to 200°F (-18 to 93°C).

Compensated Temperature Limits : 0 to 175°F (-18 to 79°C).

Pressure Limits: See chart on catalog page.

Thermal Effect : Avg 0.04%/°F (0.072%/°C) (includes zero and span).

Power Requirements : 2-wire: 10 to 35 VDC; 3-wire: 13 to 35 VDC or isolated 16 to 33 VAC (reverse polarity protected).

Output Signal : 2-wire: 4 to 20 mA; 3-wire: Field selectable 0 to 5, 1 to 5, 0 to 10, or 2 to 10 VDC.

Zero and Units: Push buttons inside the conduit enclosure.

Response Time: 400 msec.

Loop Resistance : Current output: 0 to 1250 Ω (max), Rmax = 50(Vps-10); Voltage output: Minimum load resistance = 5 kΩ.

Current Consumption : 28 mA (max).

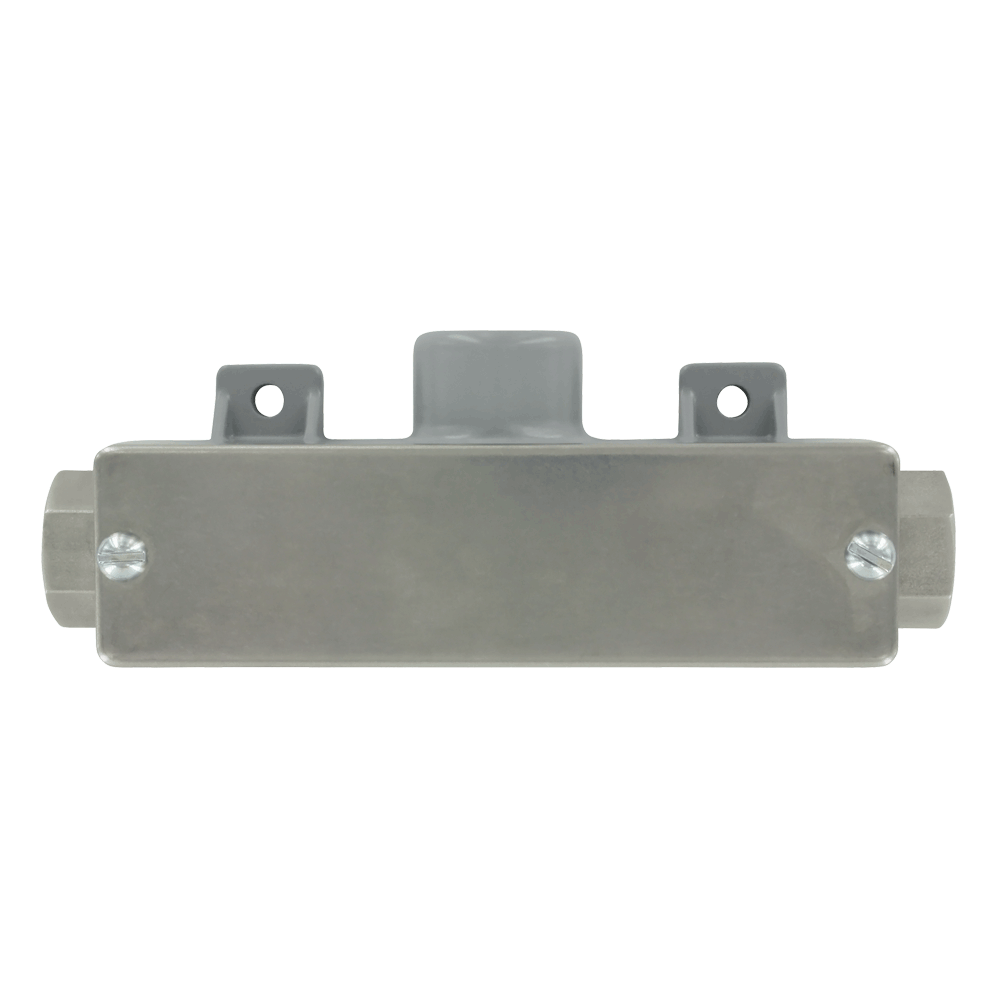

Electrical Connections: Removable terminal block; 1/2″ female NPT conduit.

Process Connections: 1/4″ female or male NPT.

Display: Optional 4-1/2 digit LCD field attachable display.

Enclosure Rating: Designed to meet NEMA 4X (IP66).

Mounting Orientation: Not position sensitive.

Weight : 629C-XX-CH: 10.1 oz (286 g); 629C-XX-R2-P1-E5-XX: 2.3 lbs (1.04 kg); 629C-XX-R6-P1-E5-XX: 4.55 lbs (2.06 kg).

Agency Approvals: CE.