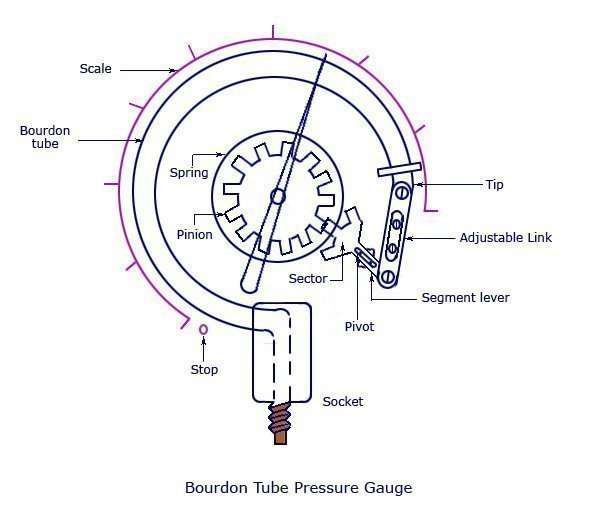

Bourdon Tubes

A Bourdon tube is a metallic coil constructed from a metal tube, closed at one end and fixed to a pressure source at the other. It has the desired elasticity that makes the tube tends to deform to straighten under pressure. The pressure applied will results in the movement at the free end causing a mechanical linkage to move a pointer. Bourdon tubes come in several forms like C tube, spiral, or helix.

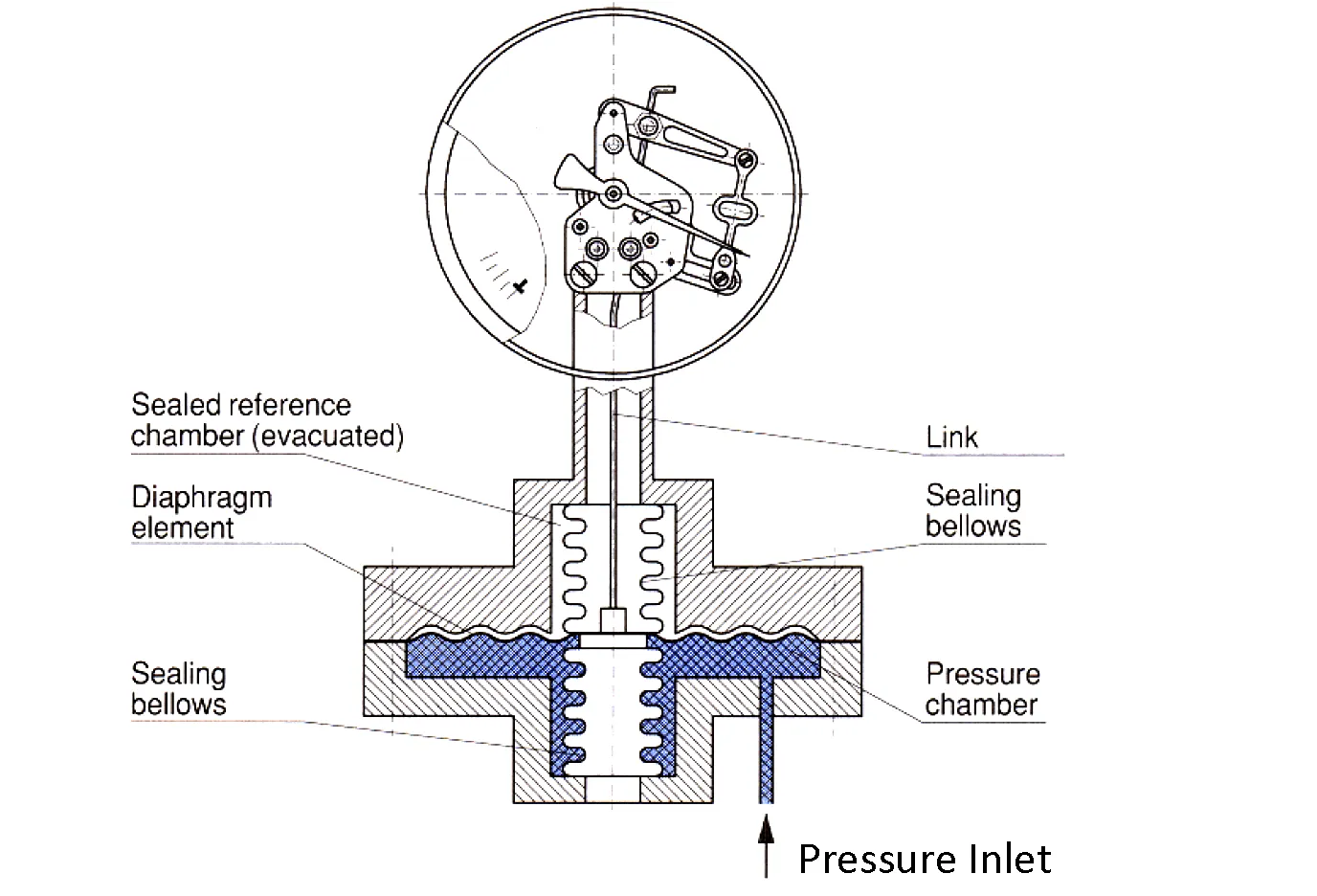

Bellows

Bellows pressure element is formed from seamless tubes that are roll-formed. It looks like thin-walled corrugated cylindrical containers hence the bellows are flexible along its axis in such a way that it will change its length proportional to the applied pressure.

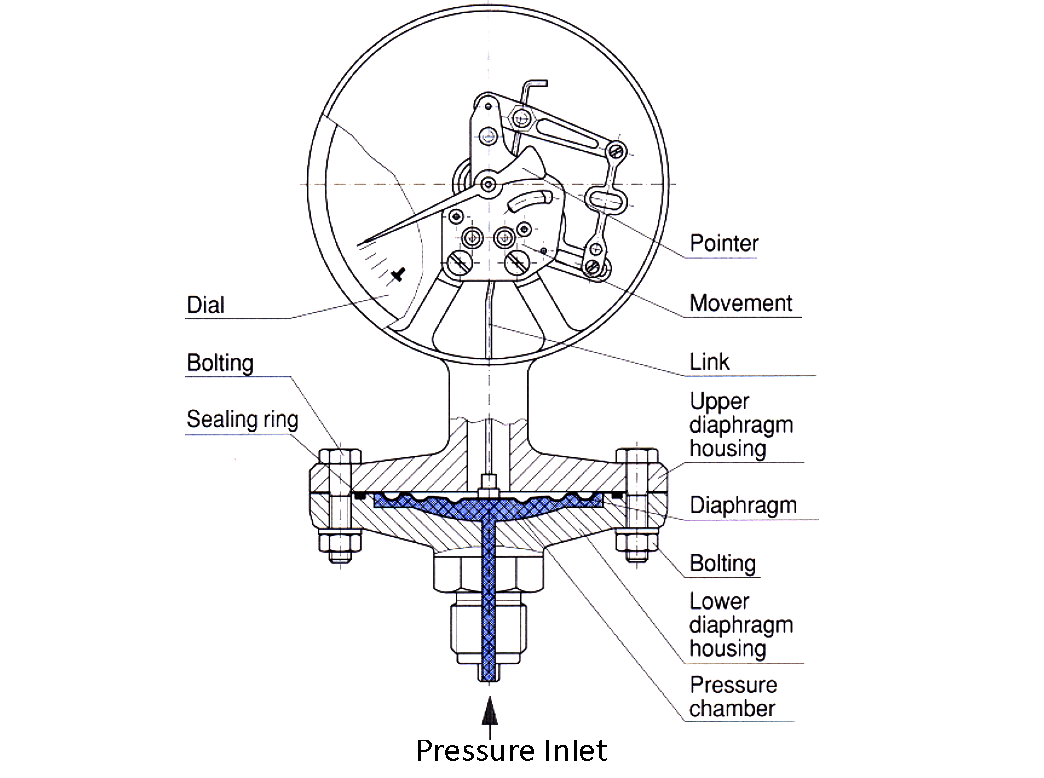

Diaphragm

The diaphragm sensor is a thin flexible metal disk, the pressure applied to one side of the disk causes a deflection that actuates a pointer. To measure very low pressures, the diaphragm requires to be very thin. In this case, it is difficult to be produced and its stability becomes poor. For this application, a capsule can be used. It is produced from two diaphragms welded together, so that doubles the displacement of the diaphragm, allowing smaller pressures to be measured without degrading its performance.