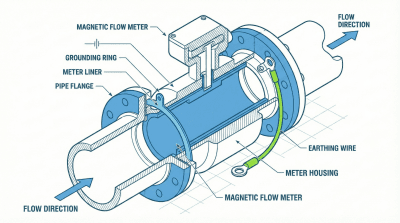

A Magnetic Flow Meter (Mag Meter) is a volumetric flow meter that uses Faraday’s Law of Induction to measure conductive liquids (water, acids, slurries).

Because they have no moving parts and a full-bore design, they are the industry standard for Wastewater, Palm Oil Effluent (POME), and Chemical Dosing.

Installation Rules (5D/3D) Mag meters require a calm flow profile.

- Upstream: Minimum 5x Diameter straight pipe.

- Downstream: Minimum 2x Diameter straight pipe.

- Position: Always install on a vertical pipe flowing UP (to ensure the pipe is full) or a horizontal pipe at the lowest point.

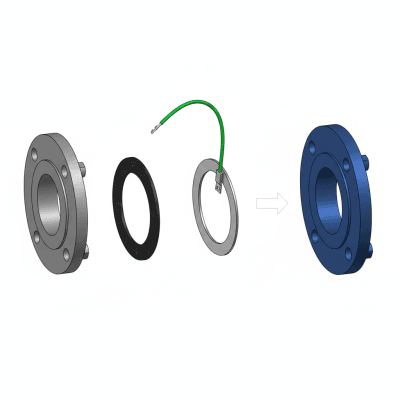

To get an accurate reading, the fluid must be grounded.

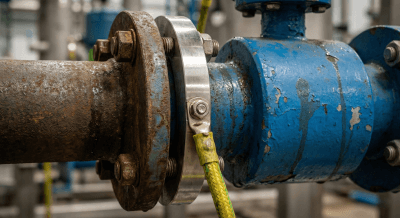

Metal Pipes: You can usually ground the meter to the pipe flanges directly.

Plastic / Lined Pipes: You MUST use Grounding Rings or a Grounding Electrode. Without this, your reading will be unstable.

💡 Expert Tip: For Chemical applications, always use Hastelloy C electrodes. For standard Water, 316 Stainless Steel is sufficient.

For General Water: Yokogawa ADMAG AXG Series (The industry standard).

For Chemical/Sanitary: Anderson-Negele IZMAG (For Food & Pharma).

For Remote Areas: [Battery Powered Mag Meter] (Perfect for irrigation).