Hysteresis is a common occurrence in various physical systems, including pressure sensing. It describes the delay or lag in a physical response to changes in external conditions or forces. In the case of pressure sensing, hysteresis can cause the diaphragm within the sensor to not immediately return to its original position after pressure changes. This can result in inaccuracies in the sensor’s readings and impact its overall performance. To optimize pressure sensing accuracy, it’s crucial to understand hysteresis and its effects on sensor performance. By identifying the sources and characteristics of hysteresis, appropriate techniques and calibration procedures can be applied to minimize or correct errors in pressure sensing. It’s important to avoid plagiarism by paraphrasing information from sources and properly citing them.

Hysteresis in Pressure Sensing

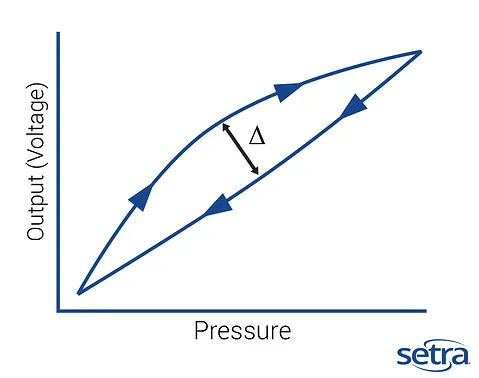

A hysteresis loop, as shown in the figure provided by Setra Systems, illustrates the changes in a pressure sensor’s output in response to variations in pressure. When pressure is applied to the sensor, the diaphragm deflects, leading to an increase in output. However, when pressure is removed, the diaphragm does not immediately return to its resting position, resulting in a delay in the sensor’s output. This delay is referred to as hysteresis and can cause inaccuracies in the sensor’s readings, negatively affecting its overall performance. Understanding hysteresis is crucial in pressure sensing to identify its sources, characteristics and calibration procedures to correct for or minimize errors in the sensor’s output.

The accuracy of a pressure sensor depends significantly on the integrity of its diaphragm. The material used to make the diaphragm and its heat treatment can have a considerable impact on the sensor’s performance and longevity. In high-precision test and measurement applications, pressure transducers need to operate reliably and safely. As a result, the diaphragms in sensors designed for these applications are typically made from stainless steel and heat-treated to maintain their strength and structural integrity. By using high-quality diaphragms in sensors, the risk of performance degradation due to diaphragm deformation or other structural defects can be minimized, ensuring accurate and consistent sensor readings over time.

Achieving accurate pressure readings in pressure sensors requires the use of high-quality materials and appropriate heat treatment during construction. Additionally, regular calibration and maintenance of the sensor can help maintain its accuracy over time. By minimizing the effects of hysteresis and ensuring the sensor’s optimal performance, its reliability and precision can be maximized. Therefore, investing in quality materials and ongoing maintenance can help to extend the sensor’s lifespan and provide reliable pressure readings for a variety of applications.

Hysteresis is a common phenomenon that occurs in pressure sensing when a change in pressure causes the diaphragm inside a pressure sensor to lag or delay in returning to its original position. This delay can impact the accuracy of the sensor’s readings. To ensure optimal performance of a pressure sensor, the diaphragm’s integrity is critical, and the material used to make it and its heat treatment can significantly affect the sensor’s performance over time. By using high-quality materials, appropriate heat treatment, and regular maintenance, one can minimize the effects of hysteresis and ensure accurate pressure readings.