Contrec New 424 Batch Controller & 425 Flow Computer

Contrec never stands still and always looking for innovative ways to make good flowmeters even better. When Contrec’s 414 Batch Controllers and 405 Flow Computers were first released in 1992, they quickly became the industry standard for accurate and reliable flow monitoring and control.

So good was the Contrec’s 400 series that many of those early instruments are still in operation over 25 years later.

When we produced the new 424 Batch Controller and 425 Flow Computer, we took all the right things our customers loved about the 400 series and added some great new features, making the 424 and 425 the best choice yet for your precise flow and batch applications.

Maintaining all the best features of the existing 400 series, including:

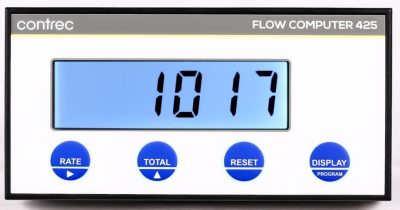

• Large LCD

• Simple four-button operation

• Easy configuration and operate

• End of batch and pump control output

• Remote start/stop/reset control

• Auto overrun and flow alarm features

• Rugged reliability

• Panel, Field or Explosion-Proof mounting

Now the Contrec 424 and 425 models also come with the following NEW features AS STANDARD:

• Adjustable ‘white’ backlight

• Tactile keypad for improved operator interaction

• RS232 & RS485 Communications

• Custom Ticket Printer Header

• Hi & Lo Flow Alarms (425 only)

• Fast response relays for high speed batching

• Software configurable input type

• Universal Mains Power Supply (AC or DC)

• Green, Red, and Orange LED status lamps

Compatible with virtually any type of pulse or frequency generating flow meters, including Turbine, Positive Displacement, Coriolis, Magnetic, and Ultrasonic, the 400 series is fully configurable to display and control in any volumetric or mass engineering units.

Having a large LCD backlit display ensures operators can see what’s happening even in dimly lit installations. In contrast, the large tactile push-buttons permit operation using gloved hands, for example, in food factories or during tanker loading applications.

The instruments come fitted with both RS232 and RS485 communication outputs. These allow the instruments to be monitored and controlled remotely from the control room. Additionally, they also will enable a ticket printer to be connected directly to the device. Many different types of ticket printers are suitable for connection to the 424 and 425. In addition to printing the process data, you can print the custom headers* at the top of each ticket to signify company name, product name, emergency telephone number, etc. (*must be factory configured).

With thousands of instruments installed worldwide, Contrec provides accurate and reliable batch and flow solutions you can count on.