In the dynamic landscape of industrial processes, efficiency is paramount. Whether you’re managing chemical production, food processing, or any other manufacturing endeavor, the precision of your operations is crucial. This is where batch controllers step in, offering a streamlined solution to optimize your production cycles.

Understanding Batch Controllers

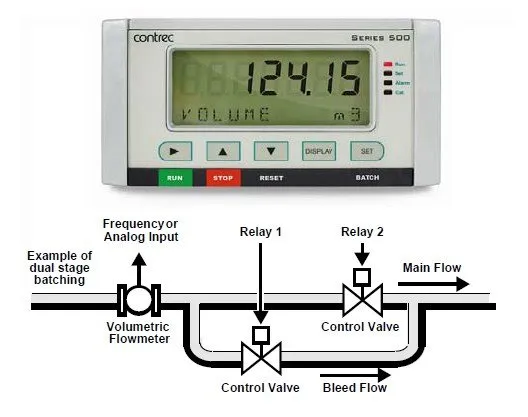

Batch controllers are automated systems designed to oversee and regulate the sequential steps of a production batch. They play a pivotal role in ensuring consistency, accuracy, and efficiency in the manufacturing process. By automating the control of various parameters, batch controllers minimize the margin of error and enhance the overall quality of the final product.

Key Features:

- Recipe Management: Store and manage multiple recipes for different products, allowing for easy switching between batches.

- Accurate Measurement: Precise measurement and control of ingredients and components, ensuring uniform product quality.

- Automated Sequencing: Streamline the production process by automating the sequential steps required for each batch.

- Data Logging: Record and store data for analysis, quality control, and regulatory compliance.

- User-Friendly Interface: Intuitive interfaces make it easy for operators to interact with and monitor the batch control system.

Advantages of Batch Controllers

- Consistency: Batch controllers ensure consistent production by precisely following predefined recipes, reducing batch-to-batch variations.

- Efficiency: Automation leads to faster and more efficient production cycles, saving both time and resources.

- Quality Assurance: Accurate measurement and control result in higher product quality, meeting industry standards and customer expectations.

- Cost Savings: Minimize waste and resource usage through optimized processes, contributing to cost-effectiveness.

- Compliance: Meet regulatory requirements and quality standards with detailed data logging and reporting capabilities.

Where to Implement Batch Controllers

- Chemical Manufacturing: Maintain precision in blending and mixing various chemicals to produce consistent batches.

- Food and Beverage Industry: Control the formulation and mixing of ingredients for food and beverage products.

- Pharmaceuticals: Ensure accuracy in the production of pharmaceuticals, where precise formulations are critical.

- Water Treatment: Optimize the dosing of chemicals in water treatment processes for reliable results.

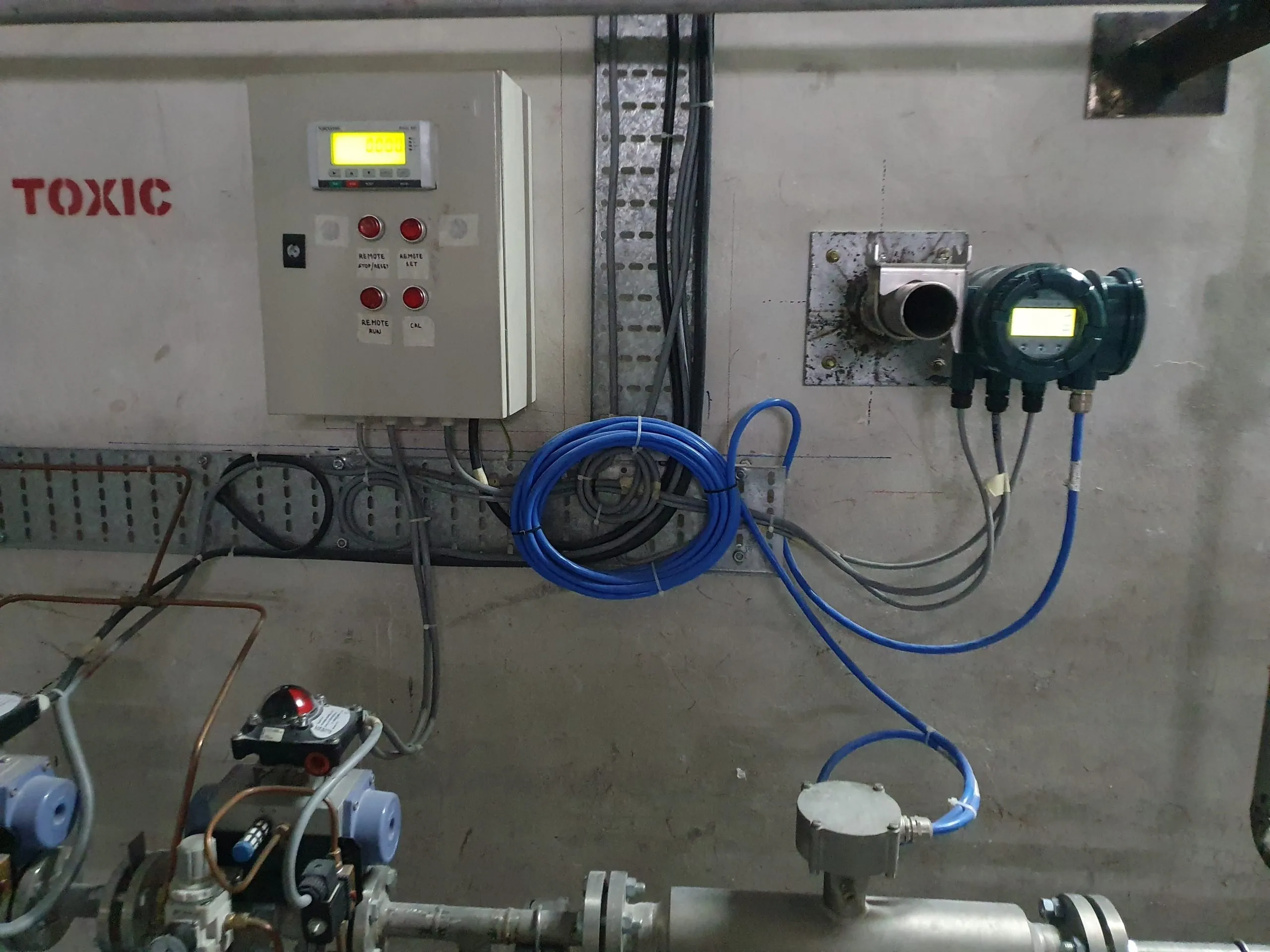

Installing Batch Controllers: A Quick Guide

- System Integration: Integrate the batch controller seamlessly into your existing production system.

- Sensor Placement: Install sensors at critical points to monitor and control variables such as temperature, pressure, and flow.

- Calibration: Regularly calibrate sensors and controllers to maintain accuracy.

- Training: Provide training to operators for efficient use and monitoring of the batch control system.

Conclusion

In the competitive landscape of modern manufacturing, optimizing efficiency is not just a preference but a necessity. Batch controllers offer a strategic advantage by automating processes, ensuring accuracy, and enhancing overall productivity. Consider integrating batch controllers into your production line to stay ahead in the relentless pursuit of operational excellence.

For a visual walkthrough of batch controller installations and real-world applications, check out the images below: